NINEIDEA:深圳是搞科技和造产品的 “超级工厂”,深圳产品设计专业不像在画室画画那么单纯,得懂技术、能落地、还得会 “搞人际关系”。

一、核心能力:别光会画图,得懂 “里外”

1. 能把新技术变成 “好用的东西”

深圳满大街都是搞 AI、智能硬件、新能源的公司,你得知道这些新技术能怎么 “玩”。比如:

- 听说有一种柔性屏技术?那能不能设计个能卷起来的手机壳?

- 比亚迪在搞电池技术,你能不能想想怎么把电池藏进电动车的车身里,让车看起来更酷?

关键:别等工程师告诉你 “能做什么”,自己要先琢磨 “用户需要什么”,再去问技术能不能实现。

2. 知道 “怎么做出来” 比 “怎么好看” 更重要

深圳周边全是工厂(东莞做模具、佛山做五金),你设计的东西得能被工厂做出来,不然就是 “纸上谈兵”。比如:

- 想设计一个圆形的塑料外壳?得先问工厂 “注塑机能不能做出这么圆的形状,会不会变形?”

- 选材料别只看颜值:便宜的 ABS 塑料容易摔裂,贵的 PC 塑料更耐摔,但成本高 —— 得根据产品卖多少钱来选。

记住:设计不是 “艺术家任性”,是 “带着镣铐跳舞”,工厂的机器和成本就是你的 “镣铐”。

3. 看透用户 “没说出来的需求”

深圳的用户很 “挑剔”,年轻人喜欢潮的,打工族喜欢实用的,老外可能喜欢简单的。怎么摸透他们?

- 接地气调研:去华强北看大爷大妈买啥手机壳,去南山科技园看白领用啥水杯,观察他们吐槽 “这东西难用在哪”。

- 别猜需求:比如设计儿童玩具,别自己想 “小孩喜欢粉色”,去幼儿园蹲点看孩子们抢着玩啥,比拍脑袋靠谱。

二、实用技能:工具要熟,还要会 “抄近道”

1. 软件别只学 PS,这些更管用

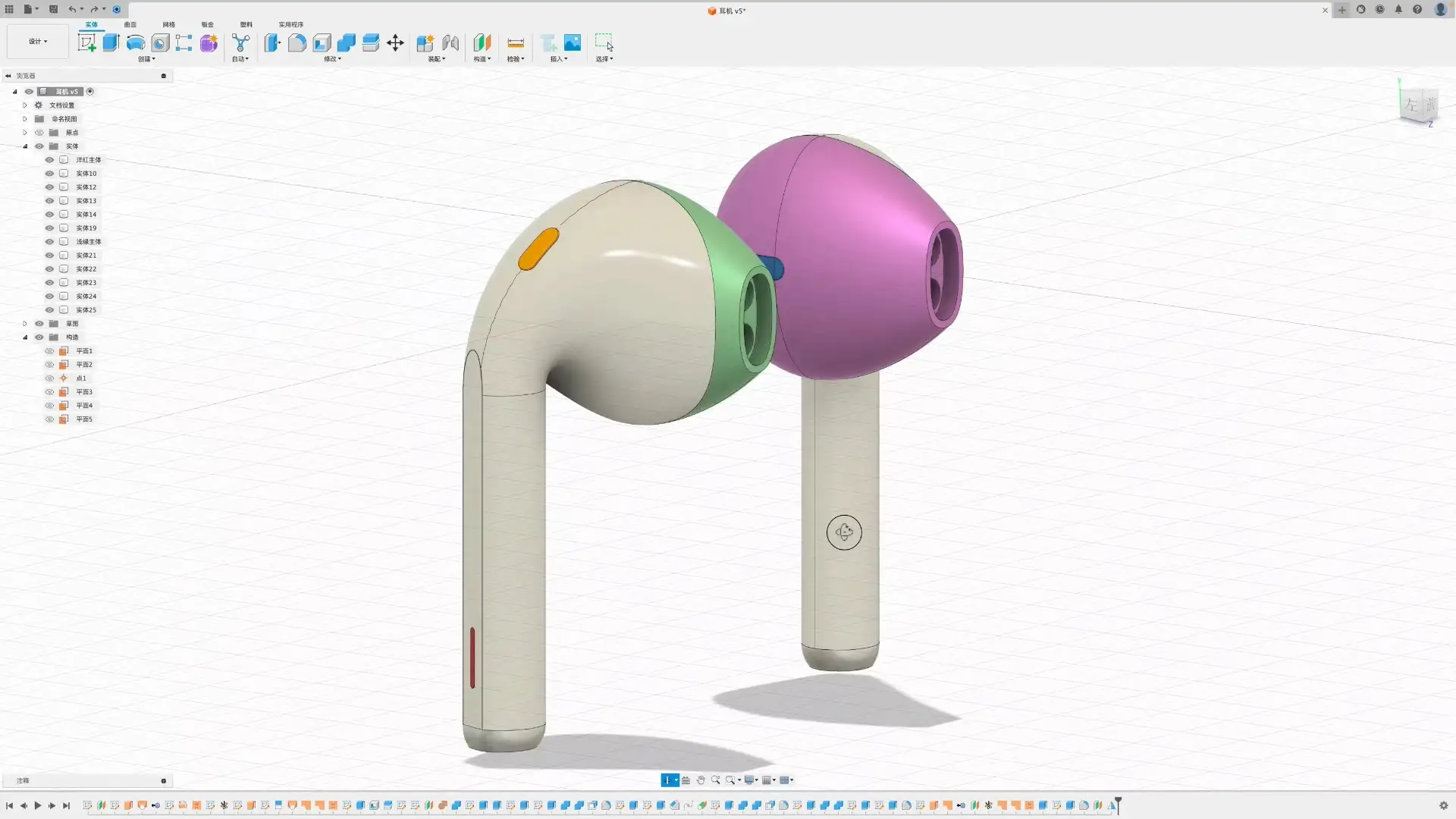

- 三维建模:

- Rhino/SolidWorks:用来画 3D 模型,比如设计一个耳机,得先用这些软件画出它的 “骨架”,工程师才能知道里面怎么放电池和芯片。

- Keyshot:画完模型后,给它 “化妆”—— 加上金属光泽、塑料质感,让老板和客户一眼看清 “这东西长啥样”。

- 做原型:

别等工厂开模!先用 3D 打印做个 “粗糙版”(比如用 PLA 材料打印个耳机外壳),自己拿在手里试试手感,不对劲马上改,省钱又快。

2. 混熟供应链,比别人快一步

- 华强北是 “宝藏库”:买个几块钱的传感器,自己鼓捣一下,看看能不能塞进设计的产品里(比如做个带温度感应的水杯)。

- 记住工厂 “潜规则”:

- 注塑厂:量大才便宜,小批量做可能用硅胶复模更省钱;

- 表面处理:喷油(喷漆)最便宜,电镀(镀金 / 银)贵但好看,选哪种得看产品定位(比如 cheap 快消品 vs 高端礼品)。

3. 别闷头设计,多和人 “吵架”

在深圳做设计,天天要和工程师、销售、老板 “Battle”:

- 和工程师沟通:别讲 “我要流线型美感”,说 “这个弧度能不能让电路板放进去?”

- 和销售聊:问问 “卖得最好的竞品有啥缺点?”(比如 “用户说按钮太小,那我们设计大一点”)

关键:能用简单的话把设计想法说清楚,比如画个草图 + 指手画脚,比讲专业术语更有用。

三、深圳 “特殊技能”:混圈子、抢时间、懂老外

1. 多逛展会,认识 “大腿”

深圳每年有高交会(全是新技术)、工业展(全是工厂),去逛的时候别光看热闹:

- 加几个工厂老板微信,以后打样、生产可能能拿到低价;

- 看看别人的产品怎么解决 “丑、贵、难用” 的问题,偷偷学来(合法借鉴!)。

2. 别磨叽!快速出方案

深圳的公司讲究 “快”,老板可能今天给需求,下周就要看初稿。怎么办?

- 用 “低保真” 快速试错:先用纸壳、橡皮泥捏个模型,甚至画个快速草图,先给老板看 “大概方向对不对”,别一上来就花三天画精美的效果图,结果方向错了全白干。

- 同时干好几件事:比如一边等工厂打样,一边改另一个项目的设计图,别闲着(深圳不养闲人~)。

3. 要是做出口产品,得懂 “水土不服”

深圳很多产品卖国外,得注意:

- 文化差异:比如给中东设计产品,别用猪的图案;给欧洲人设计,别用太艳的颜色(他们喜欢素色)。

- 合规要求:出口欧洲得符合 CE 认证(比如材料不能含重金属),设计时就得提前选对材料,别等生产了才发现不合格。

四、新人建议:别空想,多 “泡” 深圳

去工厂打工一个月:比如去东莞的注塑厂,看看工人怎么操作机器,你就知道 “设计时哪些地方容易出问题”(比如孔太小,工人没法组装)。

混设计社群:深圳有很多设计师聚会(比如工业设计协会的活动),认识同行,聊聊 “哪家工厂坑少”“哪个老板好说话”。

逛二手平台:在闲鱼看看深圳人在卖啥二手产品,差评是啥(比如 “充电口容易坏”),这些都是设计灵感来源。

深圳设计 =“务实 + 机灵 + 快”

在深圳当产品设计师,别把自己当 “艺术家”,要当 “解决问题的人”——

- 技术来了,能想到怎么用;

- 工厂问你,能说出怎么造;

- 用户吐槽,能快速改;

- 老板催你,能熬夜赶;

深圳不缺 “好看的设计”,缺的是 “能卖爆的产品”

NINEIDEA: Shenzhen is a “super factory” for technology and product manufacturing. Doing product design here is not as simple as painting in an art studio. You need to understand the technology, be able to implement it, and also be able to “manage interpersonal relationships”.

1、 Core competency: Don’t just be able to draw, you need to understand both the inside and outside

- Can turn new technologies into “useful things”

Shenzhen is full of companies engaged in AI, intelligent hardware, and new energy, and you need to know how these new technologies can be “played”. For example:

I heard there is a flexible screen technology? Can you design a phone case that can be rolled up?

BYD is developing battery technology. Can you think of how to hide the battery inside the body of an electric vehicle to make it look cooler?

Key: Don’t wait for engineers to tell you ‘what can be done’, first figure out ‘what users need’, and then ask if technology can achieve it.

2.Knowing ‘how to make it’ is more important than ‘how to look good’

Shenzhen is surrounded by factories (Dongguan makes molds, Foshan makes hardware), and what you design must be able to be made by the factories, otherwise it’s just talk on paper. For example:

Do you want to design a circular plastic casing? Can the injection molding machine make such a round shape? Will it deform

Don’t just focus on appearance when choosing materials: cheap ABS plastic is prone to breakage, while expensive PC plastic is more resistant to breakage, but the cost is high – it depends on how much the product is sold for.

Remember: design is not “artist’s whims”, it is “dancing with shackles”, the machines and costs of the factory are your “shackles”.

- Identify users’ unspoken needs

Users in Shenzhen are very picky, young people prefer trendy, working people prefer practical, and foreigners may prefer simple. How do you figure them out?

Grounding survey: go to Huaqiangbei to see what mobile phone covers parents buy, go to Nanshan Science Park to see what water cups white-collar workers use, and watch them roast about “where is this thing difficult to use”.

Don’t guess the demand: for example, designing children’s toys, don’t think ‘children like pink’ yourself, go to kindergarten and watch what children are competing to play with, it’s more reliable than patting their heads.

2、 Practical skills: Familiar with tools and able to take shortcuts

- Don’t just learn Photoshop software, these are more effective

3D modeling:

Rhino/SolidWorks: Used to draw 3D models, such as designing a headphone, engineers need to use these software to draw its “skeleton” first, so that they can know how to put the battery and chip inside.

Keyshot: After drawing the model, apply “makeup” to it – adding metallic luster and plastic texture, allowing the boss and clients to see “what this thing looks like” at a glance.

Prototype making:

Don’t wait for the factory to open the mold! First, use 3D printing to make a “rough version” (such as printing a headphone case with PLA material), and try to feel it in your hand. If it doesn’t feel good, you can change it immediately, saving money and being fast.

- Familiarize the supply chain and be one step ahead of others

Huaqiangbei is a ‘treasure trove’: buy a sensor for a few yuan, tinker with it yourself, and see if it can fit into the designed product (such as making a water cup with temperature sensing).

Remember the ‘unwritten rules’ of the factory:

Injection molding factory: Large quantities are cheaper, while small batches may be more cost-effective by using silicone molds;

Surface treatment: Oil spraying (spray painting) is the cheapest, electroplating (gold/silver plating) is expensive but looks good. The choice depends on the product positioning (such as cheap fast-moving consumer goods vs high-end gifts).

- Don’t keep your head down when designing, argue more with people

In Shenzhen, doing design requires daily battles with engineers, salespeople, and bosses:

Communicate with engineers: Don’t say ‘I want streamlined aesthetics’, say’ Can this curve fit the circuit board in? ‘

Chat with the salesperson: Ask “What are the shortcomings of the best-selling competitor?” (e.g. “The user says the button is too small, so let’s design it bigger”)

Key: Being able to articulate design ideas in simple words, such as sketching and pointing fingers, is more useful than using professional jargon.

3、 Shenzhen’s’ special skills’: mixing circles, seizing time, understanding foreigners

- Visit more exhibitions and get to know the ‘thighs’

Every year in Shenzhen, there is a high-tech fair (full of new technologies) and an industrial exhibition (full of factories). When you go there, don’t just watch the excitement:

Add a few factory owners’ WeChat accounts, and in the future, you may be able to get low prices for sampling and production;

Take a look at how other people’s products solve the problems of being “ugly, expensive, and difficult to use”, and secretly learn from them (legal reference!).

- Don’t grind! Quickly come up with a solution

Companies in Shenzhen emphasize “speed”, and the boss may give a demand today, but next week they need to review the initial draft. What should I do?

Quick trial and error with “low fidelity”: First, pinch a model with a paper case or rubber clay, or even draw a quick sketch, and show the boss if the “general direction is correct”. Don’t spend three days drawing exquisite renderings right away, only to end up with nothing if the direction is wrong.

Doing several things at the same time, such as waiting for the factory to make samples while modifying the design of another project, don’t be idle (Shenzhen doesn’t have idle people).

If you want to export products, you have to understand the saying ‘adapt to the local conditions’

Many products in Shenzhen are sold abroad, so be aware of:

Cultural differences: For example, when designing products for the Middle East, avoid using pig patterns; Design for Europeans, don’t use too bright colors (they prefer plain colors).

Compliance requirements: Exporting to Europe must comply with CE certification (such as materials not containing heavy metals), and materials must be selected in advance during design to avoid discovering non conformities during production.

4、 Newcomer advice: Don’t daydream, spend more time in Shenzhen

Go to a factory to work for a month: for example, go to an injection molding factory in Dongguan and see how the workers operate the machines. You will know “which parts are prone to problems during design” (such as holes that are too small for workers to assemble).

Mixed design community: There are many designer gatherings in Shenzhen (such as events organized by the Industrial Design Association) to meet peers and chat about “which factory has fewer pitfalls” and “which boss is easy to talk to”.

Strolling through second-hand platforms: Take a look at what second-hand products Shenzhen people are selling and what negative reviews they have (such as “charging ports are prone to breakage”) at Xianyu. These are all sources of design inspiration.

Shenzhen design=”pragmatic+clever+fast”

When working as a product designer in Shenzhen, don’t consider yourself an “artist”, be a “problem solver”——

Technology has arrived, can you think of how to use it;

The factory asks you, can you tell me how to make it;

Users can quickly correct roast;

The boss urges you to stay up late to catch up;

Shenzhen does not lack “good-looking designs”,

what it lacks is “products that can sell well”.