九号创新:深圳工业设计流程与国外主流设计流程(如欧美设计思维、日本精益设计、北欧人文设计)的核心差异,本质是 “产业生态驱动” 与 “设计理念驱动”*的路径分野 —— 前者依托深圳完整的硬件产业链,形成 “快速落地、商业闭环” 的实战型流程;后者基于成熟的设计体系,侧重 “人文关怀、长期价值” 的深度创新。以下中外工业设计流程对比从核心维度对比差异、优劣势,并结合实操场景给出适配建议:

@NINEIDEA九号创新 www.nineidea.com

一、核心维度对比表(清晰直观,便于落地参考)

| 对比维度 | 深圳工业设计流程 | 国外主流设计流程(以欧美 / 日本为例) |

|---|---|---|

| 核心逻辑 | 「用户痛点→快速原型→供应链落地→商业变现」闭环 | 「人文需求→理念创新→技术验证→生态延伸」长期主义 |

| 设计起点 | 市场需求 + 供应链可行性(先考虑 “能不能快速量产”) | 用户体验 + 社会价值(先考虑 “是否解决本质问题”) |

| 供应链协同 | 早期深度绑定(设计阶段即对接模具厂 / 元器件商) | 后期对接(设计方案定型后再匹配供应链) |

| 创新导向 | 应用型创新(功能优化、结构简化、成本控制) | 原创性创新(技术突破、模式重构、人文关怀) |

| 时间周期 | 短平快(小型产品 30-60 天完成从设计到量产) | 长周期(中型产品 6-12 个月,需多轮验证) |

| 成本控制 | 极致优化(依托本地供应链,打样 / 量产成本降低 30%-50%) | 成本容忍度高(优先保证设计品质,不刻意压缩成本) |

| 团队构成 | 跨学科实战团队(工业设计师 + 结构工程师 + 供应链专员) | 专业化细分团队(用户研究员 + 交互设计师 + 工程团队) |

| 核心工具 / 方法 | DFM(可制造性设计)、模块化设计、敏捷迭代 | 设计思维(Design Thinking)、精益设计、用户共创 |

| 落地重点 | 商业转化效率(电商爆款、渠道适配、性价比) | 长期价值(品牌溢价、用户忠诚度、社会影响) |

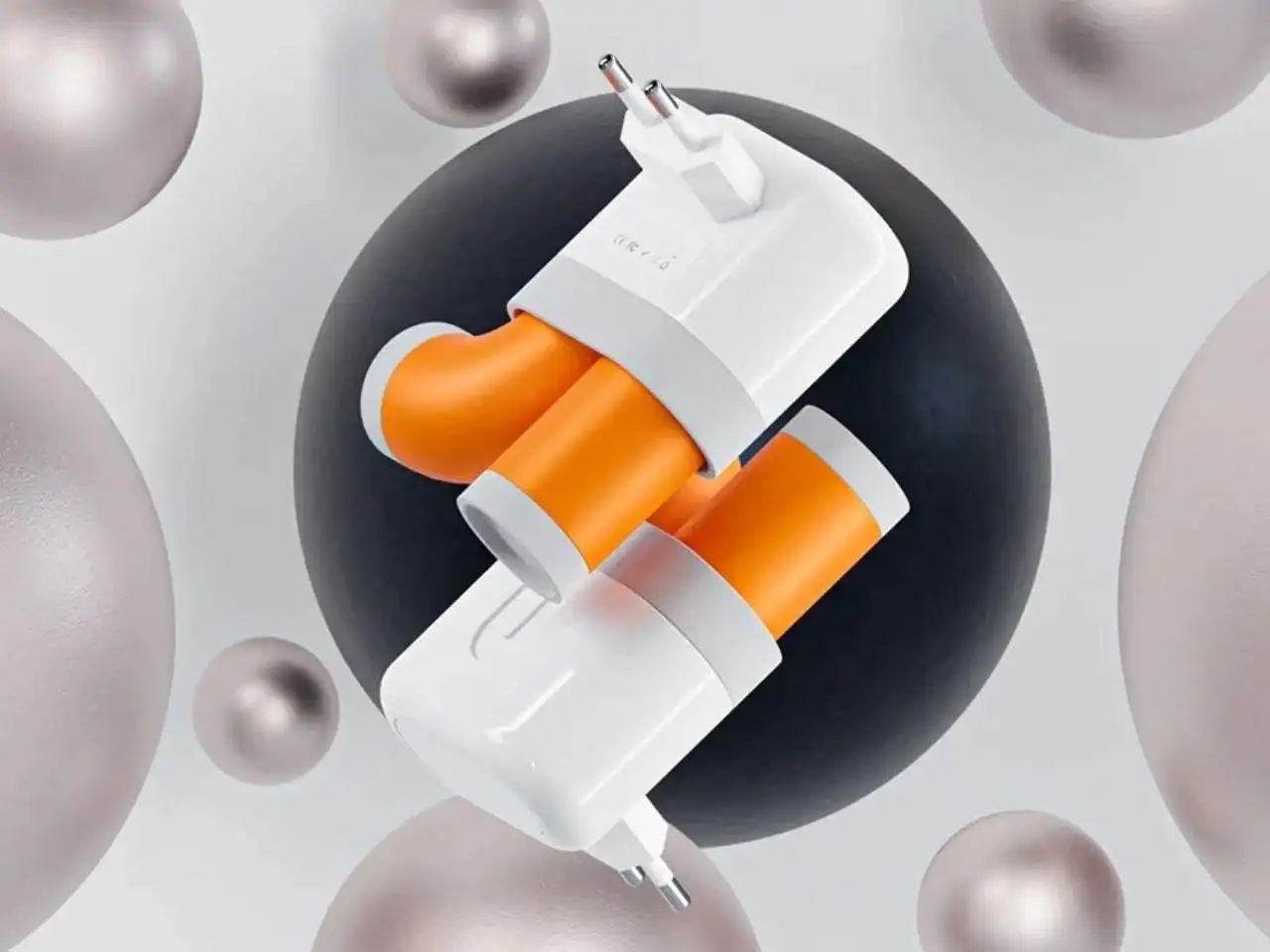

| 典型案例 | 大疆无人机(12 轮快速迭代优化机身结构)、奥海快充(模块化适配多场景) | 苹果 iPhone(5 年研发周期,重构手机交互逻辑)、宜家家具(可持续材料 + 人性化收纳) |

二、各自优劣势深度解析(结合实操场景,避免空泛)

(一)深圳工业设计流程:优势在 “落地效率”,短板在 “深度创新”

核心优势(适配 “快速抢占市场” 场景)

- 供应链协同效率碾压:设计公司与模具厂、元器件商平均距离不超过 50 公里,支持 “72 小时快速打样、15 天小批量试产”—— 比如深圳某智能硬件公司,通过本地供应链实现 “设计方案修改后 48 小时出新版原型”,而国外同类项目需 2-3 周。

- 商业变现能力强:从设计到电商上架的周期极短,适合 “爆款逻辑”—— 比如深圳小家电设计,往往针对某一细分痛点(如 “便携快充”“静音设计”)做极致优化,快速占领中低端市场,ROI(投资回报率)可在 6-12 个月内兑现。

- 成本控制能力突出:模块化设计 + 通用件采购 + 本地供应链竞争,让产品成本比国外同类低 30%-50%—— 比如深圳产的便携投影仪,成本仅为欧美品牌的 1/3,却能满足 80% 的用户需求。

- 敏捷迭代适配市场:基于销售数据和用户反馈,快速调整设计(如外观颜色、功能配置),适合 “需求多变的消费电子市场”—— 比如深圳耳机品牌,可根据电商评论快速优化耳罩材质,迭代周期仅需 2 周。

明显短板(需规避 “同质化陷阱”)

- 原创性不足,易陷入同质化:过度依赖 “市场跟风 + 功能模仿”,缺乏底层技术创新 —— 比如深圳智能手表多在 “续航、屏幕大小” 上做文章,而国外品牌(如苹果 Watch)已切入 “健康监测 + 生态联动” 的原创赛道。

- 长期价值弱化:重 “短期销量” 轻 “品牌沉淀”,部分产品忽视可持续性(如一次性塑料外壳)和用户体验细节(如操作逻辑复杂)。

- 设计体系化不足:缺乏统一的设计标准和人才培养体系,依赖 “经验型设计师”,流程规范性弱于国外。

(二)国外主流设计流程:优势在 “深度创新”,短板在 “落地效率”

核心优势(适配 “打造高端品牌” 场景)

- 原创性与人文关怀极致:聚焦用户本质需求,而非表面痛点 —— 比如北欧家具设计,不仅解决 “收纳” 问题,更通过 “自然材质 + 极简造型” 传递 “舒适生活” 理念;日本精益设计(如无印良品),追求 “去冗余、重本质”,让产品兼具实用性与精神价值。

- 设计体系化、标准化:依托成熟的设计方法论(如斯坦福 d.school 的 “共情 – 定义 – 构思 – 原型 – 测试” 五步法),流程规范、风险可控 —— 比如德国工业设计,从概念到量产需经过 “用户调研→技术评审→伦理审查→可持续性评估” 多轮验证,产品故障率远低于行业平均。

- 品牌溢价能力强:通过原创设计和长期价值积累,形成高品牌壁垒 —— 比如苹果、索尼等品牌,设计溢价可达产品成本的 2-3 倍,用户忠诚度极高。

- 可持续性设计领先:提前布局环保材料、循环利用方案 —— 比如欧美家电品牌,设计阶段即考虑产品报废后的拆解回收,符合全球碳中和趋势。

明显短板(需规避 “效率低下” 陷阱)

- 落地周期长、成本高:设计方案需经过多轮学术化验证,供应链对接成本高 —— 比如欧洲某智能穿戴设备,从设计到量产耗时 10 个月,打样成本是深圳的 3 倍。

- 对市场变化响应迟钝:长期主义导致迭代速度慢,难以适配 “快速变化的消费市场”—— 比如国外某老牌相机品牌,因坚持传统设计理念,未能及时跟进 “便携化、智能化” 趋势,市场份额被深圳品牌挤压。

- 供应链适配性弱:国外供应链分散,缺乏深圳 “一站式” 配套能力,导致部分创新设计难以量产(如特殊材质、复杂结构)。

三、实操适配建议(结合工业设计场景,直接套用)

作为拥有近二十年经验的工业设计师,可根据项目定位、市场周期、预算灵活选择或融合两种流程:

- 若做 “电商爆款 / 快速变现项目”:优先采用深圳流程,聚焦 “供应链协同 + 成本控制”—— 比如设计便携小家电,可先对接深圳本地模具厂,确定可量产的结构方案,再通过快速迭代优化外观和功能,3 个月内完成从设计到上架。

- 若做 “高端品牌 / 长期项目”:借鉴国外流程的 “深度调研 + 原创理念”,搭配深圳的 “供应链落地能力”—— 比如设计高端智能家具,先通过用户共创挖掘 “居家办公 + 健康监测” 的本质需求,形成原创设计方案,再利用深圳供应链实现模块化量产,平衡创新与效率。

- 若做 “跨境出口项目”:需融合两者优势 —— 比如针对欧美市场,需符合当地 “可持续性设计标准”(如欧盟 CE 认证),采用国外的 “用户调研方法论”,同时通过深圳供应链控制成本,确保产品在 “合规性、原创性、性价比” 上形成竞争力。

四、总结:没有 “最优流程”,只有 “最适配场景”

- 深圳流程的核心竞争力是 “产业生态赋能的落地效率”,适合 “短周期、高性价比、快速占领市场” 的项目;

- 国外流程的核心竞争力是 “设计体系支撑的长期价值”,适合 “长周期、高溢价、打造品牌壁垒” 的项目。

未来的趋势是 “融合创新”—— 深圳设计师可借鉴国外的 “深度调研、原创理念”,弥补同质化短板;国外品牌可利用深圳的 “供应链效率、敏捷迭代”,加快创新落地。对于实操型设计师而言,关键是 “取两者之长”:用国外的设计思维挖掘本质需求,用深圳的产业生态实现快速变现。

Comparison of advantages and disadvantages of industrial design processes between China and foreign countries

NINEIDEA: the core difference between Shenzhen’s industrial design process and foreign mainstream design processes (such as European and American design thinking, Japanese lean design, Nordic humanistic design) is essentially the path separation between “industrial ecology driven” and “design concept driven” * – the former relies on Shenzhen’s complete hardware industry chain to form a practical process of “rapid landing, commercial closed-loop”; The latter is based on a mature design system, focusing on deep innovation of “humanistic care and long-term value”. The following comparison of industrial design processes between China and foreign countries highlights the differences, strengths, and weaknesses in core dimensions, and provides adaptation suggestions based on practical scenarios:

1、 Core dimension comparison table (clear and intuitive, easy to reference for implementation)

| Comparative dimension | Shenzhen Industrial Design Process | Mainstream design processes abroad (taking Europe, America/Japan as examples) |

|---|---|---|

| Core logic | Closed loop of “user pain points → rapid prototyping → supply chain implementation → commercial monetization” | Long termism of “humanistic needs → conceptual innovation → technological verification → ecological extension” |

| Design starting point | Market demand+supply chain feasibility (considering first whether it can be quickly mass-produced) | User experience+social value (first consider whether it solves the fundamental problem) |

| Supply chain collaboration | Early deep binding (connecting with mold factories/component suppliers during the design phase) | Post docking (matching the supply chain after the design scheme is finalized) |

| Innovation oriented | Applied innovation (functional optimization, structural simplification, cost control) | Original innovation (technological breakthroughs, model reconstruction, humanistic care) |

| Time period | Short, flat and fast (small products can be completed from design to mass production in 30-60 days) | Long cycle (6-12 months for medium-sized products, requiring multiple rounds of verification) |

| Cost control | Ultimate optimization (relying on local supply chain, reducing sampling/mass production costs by 30% -50%) | High cost tolerance (prioritizing design quality and not intentionally reducing costs) |

| Team Composition | Interdisciplinary practical team (industrial designer+structural engineer+supply chain specialist) | Specialized segmentation team (user researcher+interaction designer+engineering team) |

| Core Tools/Methods | DFM (Design for Manufacturing), modular design, agile iteration | Design Thinking, Lean Design, User Co Creation |

| Key landing points | Business conversion efficiency (e-commerce bestsellers, channel adaptation, cost-effectiveness) | Long term value (brand premium, user loyalty, social impact) |

| Typical Case | DJI drone (12 rounds of rapid iterative optimization of fuselage structure), Aohai fast charging (modular adaptation to multiple scenarios) | Apple iPhone (5-year development cycle, restructuring mobile interaction logic), IKEA Furniture (sustainable materials+humanized storage) |

2、 Deep analysis of their respective strengths and weaknesses (combined with practical scenarios to avoid being vague)

(1) Shenzhen industrial design process: advantages lie in “landing efficiency”, weaknesses lie in “deep innovation”

Core advantage (adapted to the scenario of “quickly seizing the market”)

Supply chain collaboration efficiency crushing: The average distance between design companies and mold factories and component suppliers is no more than 50 kilometers, supporting “72 hour rapid sampling and 15 day small batch trial production” – for example, a smart hardware company in Shenzhen achieved “new version prototypes within 48 hours after design scheme modification” through local supply chain, while similar projects abroad require 2-3 weeks.

Strong commercial monetization ability: The cycle from design to e-commerce listing is extremely short, suitable for “explosive logic” – such as Shenzhen small home appliance design, often targeting a specific pain point (such as “portable fast charging” and “silent design”) for extreme optimization, quickly occupying the mid to low end market, and ROI (return on investment) can be realized within 6-12 months.

Outstanding cost control ability: modular design+general parts procurement+local supply chain competition, making product costs 30% -50% lower than similar products abroad – for example, portable projectors produced in Shenzhen have a cost only one-third of European and American brands, but can meet 80% of user needs.

Agile iterative adaptation market: Based on sales data and user feedback, quickly adjust the design (such as appearance color, functional configuration), suitable for the “ever-changing consumer electronics market” – such as Shenzhen headphone brands, can quickly optimize the material of the earmuffs according to e-commerce reviews, and the iteration cycle only takes 2 weeks.

Obvious shortcomings (need to avoid the “homogenization trap”)

Lack of originality and susceptibility to homogenization: excessive reliance on “market trends+functional imitation”, lack of underlying technological innovation – for example, Shenzhen smartwatches often focus on “battery life and screen size”, while foreign brands (such as Apple Watch) have entered the original track of “health monitoring+ecological linkage”.

Long term value weakening: focusing on “short-term sales” rather than “brand sedimentation”, some products neglect sustainability (such as disposable plastic shells) and user experience details (such as complex operating logic).

Lack of systematic design: Lack of unified design standards and talent cultivation system, reliance on “experienced designers”, and weaker process standardization compared to foreign countries.

(2) The mainstream design process abroad: advantages lie in “deep innovation”, weaknesses lie in “landing efficiency”

Core advantage (adapted to the scenario of “building high-end brands”)

Originality and ultimate humanistic care: Focusing on the essential needs of users, rather than surface pain points – for example, Nordic furniture design not only solves the problem of “storage”, but also conveys the concept of “comfortable life” through “natural materials+minimalist styling”; Japanese lean design (such as MUJI) pursues “eliminating redundancy and emphasizing essence”, making products both practical and spiritually valuable.

Systematization and standardization of design: relying on mature design methodologies (such as Stanford’s “Empathy Definition Concept Prototype Testing” five step method), standardized processes, and controllable risks – for example, in German industrial design, from concept to mass production, multiple rounds of verification are required through “user research → technical evaluation → ethical review → sustainability assessment”, and the product failure rate is much lower than the industry average.

Strong brand premium capability: Through original design and long-term value accumulation, high brand barriers are formed – such as brands like Apple and Sony, where design premiums can reach 2-3 times the product cost and user loyalty is extremely high.

Leading in Sustainable Design: Pre layout of environmentally friendly materials and recycling solutions – for example, European and American home appliance brands consider dismantling and recycling of scrapped products during the design phase, in line with the global trend towards carbon neutrality.

Obvious shortcomings (need to avoid the trap of “low efficiency”)

Long implementation cycle and high cost: The design scheme requires multiple rounds of academic verification, and the cost of supply chain integration is high – for example, a smart wearable device in Europe took 10 months from design to mass production, and the cost of sampling was three times that of Shenzhen.

Slow response to market changes: Longtermism leads to slow iteration speed, making it difficult to adapt to the “rapidly changing consumer market” – for example, a well-established foreign camera brand failed to follow the trend of “portability and intelligence” in a timely manner due to its adherence to traditional design concepts, resulting in market share being squeezed by Shenzhen brands.

Weak supply chain adaptability: Foreign supply chains are scattered and lack Shenzhen’s “one-stop” supporting capabilities, which makes it difficult to mass produce some innovative designs (such as special materials and complex structures).

3、 Practical adaptation suggestions (combined with industrial design scenarios, directly applied)

As an industrial designer with nearly 20 years of experience, I can flexibly choose or integrate two processes based on project positioning, market cycle, and budget:

If you are working on an “e-commerce hot selling/fast monetization project”: prioritize using the Shenzhen process and focus on “supply chain collaboration+cost control” – for example, when designing portable small appliances, you can first connect with a local mold factory in Shenzhen to determine a structure plan that can be mass-produced, and then optimize the appearance and functionality through rapid iteration. Complete the design and listing process within 3 months.

If you are doing a “high-end brand/long-term project”: draw on the “in-depth research+original concept” of foreign processes, and combine it with Shenzhen’s “supply chain landing capability” – such as designing high-end smart furniture, first explore the essential needs of “working from home+health monitoring” through user co creation, form an original design plan, and then use Shenzhen’s supply chain to achieve modular mass production, balancing innovation and efficiency.

If doing a ‘cross-border export project’: it is necessary to integrate the advantages of both – for example, for the European and American markets, it is necessary to comply with local ‘sustainable design standards’ (such as EU CE certification), adopt foreign’ user research methodology ‘, and control costs through the Shenzhen supply chain to ensure that the product is competitive in terms of’ compliance, originality, and cost-effectiveness’.

4、 Summary: There is no ‘optimal process’, only’ most suitable scenario ‘

The core competitiveness of Shenzhen’s processes lies in the “landing efficiency empowered by industrial ecology”, which is suitable for projects that are “short cycle, high cost-effectiveness, and quickly occupy the market”;

The core competitiveness of foreign processes lies in the long-term value supported by the design system, which is suitable for projects with long cycles, high premiums, and brand barriers.

The future trend is “integrated innovation” – Shenzhen designers can learn from foreign “in-depth research and original ideas” to make up for the shortcomings of homogenization; Foreign brands can leverage Shenzhen’s “supply chain efficiency and agile iteration” to accelerate innovation implementation. For practical designers, the key is to “take the strengths of both”: using foreign design thinking to explore essential needs, and using Shenzhen’s industrial ecology to achieve rapid monetization.