九号创新:作为 “设计之都” 和全球硬件制造中心,深圳产品设计流程融合了用户洞察、技术创新、供应链协同与商业落地的全链条优势。以下文章将系统拆解深圳产品设计的核心流程、方法论及地域特色,结合标杆案例展现其高效迭代的底层逻辑:

@NINEIDEA九号创新 www.nineidea.com

一、流程总纲:深圳设计的核心逻辑

深圳产品设计以 “用户价值 × 商业效率” 为核心公式,形成 “洞察 – 设计 – 验证 – 落地 – 迭代” 的闭环流程。区别于传统设计模式,其突出优势在于:

- 本地化供应链响应(平均打样周期比行业短 30%)

- 跨学科协同设计(工业设计 + 工程技术 + 市场运营)

- 政策支持下的标准化体系(地方标准 GB/T 33635-2017 配套)

- 数据驱动的快速迭代机制

二、六大核心流程阶段详解

(一)需求洞察:爆款的起点是真实痛点

核心目标:从用户场景中挖掘未被满足的需求,明确产品定位

深圳特色方法论:

- 沉浸式场景调研:如鼎典创造体通过模拟家庭 / 办公 / 户外场景,捕捉潜在需求

- 用户共创模式:努比亚大白充电器的 Type-C 接口设计,源于 1200 + 用户反馈

- 三维验证体系:市场数据(竞品分析)+ 用户反馈(问卷 / 访谈)+ 技术可行性(工程师预审)

输出物:《用户画像报告》《需求优先级矩阵》《技术可行性评估表》

(二)方案设计:技术与美学的平衡术

核心目标:将需求转化为可落地的设计方案,兼顾创新与量产性

关键动作:

- 跨学科融合:无人机设计整合电子工程(芯片选型)、机械结构(机身稳定性)与工业设计(空气动力学外观)

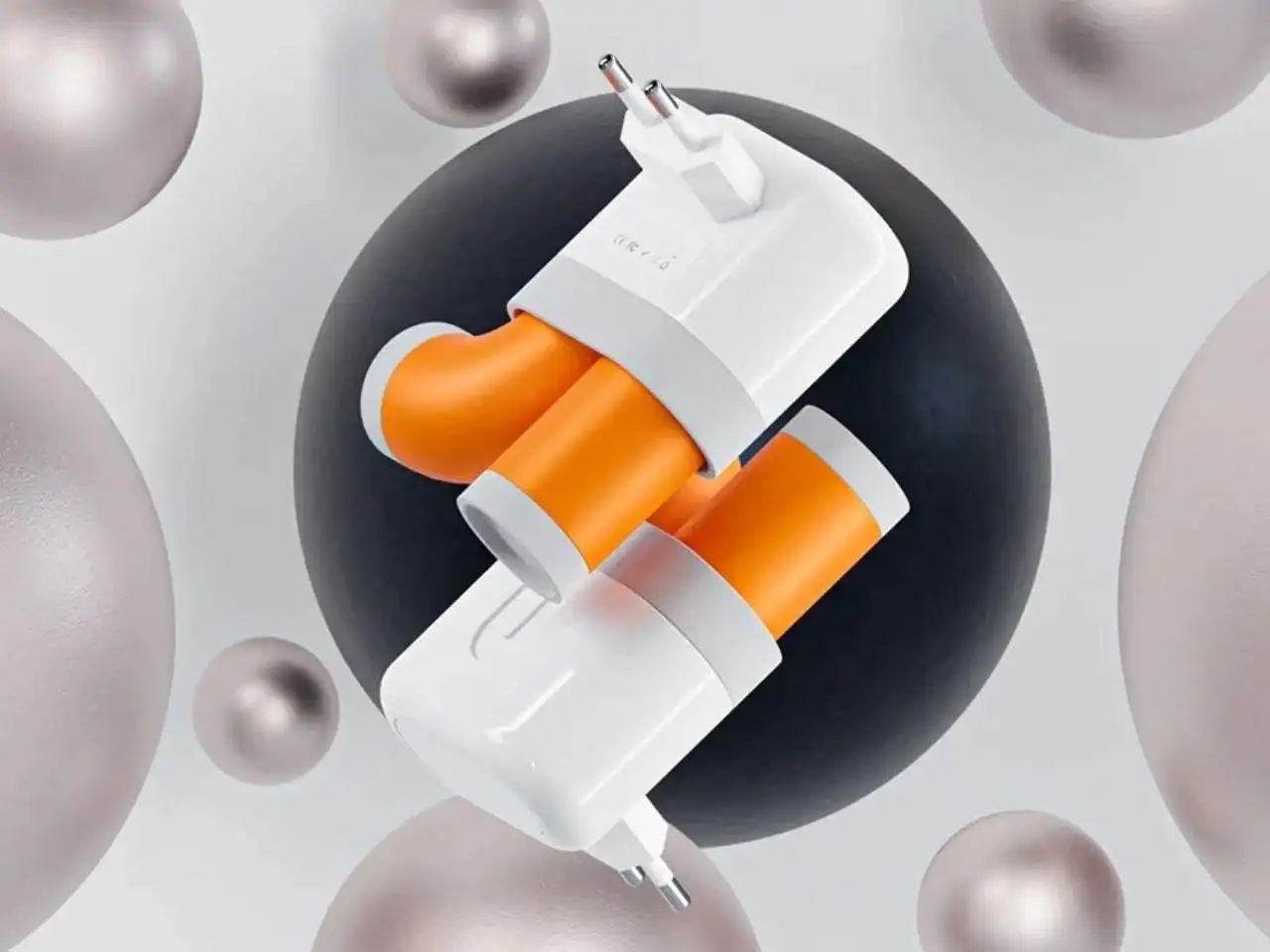

- 模块化架构:奥海充放电一体枪采用枪盒一体化结构,可更换部件降低 30% 维修成本

- 视觉语言定义:结合品牌调性与用户偏好,输出情绪板(moodboard)及色彩 / 材质规范

(三)原型验证:用迭代降低试错成本

核心目标:通过快速原型测试,验证设计可行性与用户体验

深圳效率密码:

- 敏捷开发循环:采用 “设计 – 测试 – 迭代” 短周期模式,大疆无人机通过 12 轮风洞实验优化机身曲线

- 数字孪生技术:虚拟仿真测试替代部分物理原型,研发周期缩短 40%

- 多维度评审:内部跨部门评审(设计 + 工程 + 供应链)+ 用户实测(小范围种子用户)

输出物:高保真原型、测试报告、设计修改清单

(四)供应链落地:从图纸到产品的闭环

核心优势:深圳拥有全国最完整的电子硬件产业链,设计公司与模具厂、材料商平均距离不超过 50 公里

关键动作:

- 本地化协同:九号创新在吹风机项目中,通过本地供应链实现紫色金属漆面 72 小时快速定制

- 成本优化:标准化部件采购(如 Type-C 接口通用化)+ 模块化生产,努比亚充电器成本降低 25%

- 量产保障:产前工艺评审(DFM 可制造性设计)+ 小批量试产(50-100 件),九号创新设计量产转化率达 92%

(五)市场转化:设计赋能商业价值

核心逻辑:让设计成为品牌传播的载体,精准触达目标用户

方法论:

- 故事化设计:儿童电动摩托车保留经典油箱造型,唤醒品牌情怀

- 精准渠道匹配:环保产品侧重社交媒体(传播环保理念),创新硬件优先众筹平台(验证市场)

- 卖点提炼:直击核心需求,如 “便携快充”“静音设计” 等具象化表达

(六)持续迭代:爆款的长效运营

核心目标:基于市场反馈持续优化,构建产品生态

关键动作:

- 数据驱动优化:分析销售数据(如亚马逊评论关键词)与用户行为数据,迭代功能

- 知识产权布局:申请外观 / 结构专利,某公司设计累计服务华为、联想等企业,获 3000 + 专利

- 生态延伸:浪尖设计通过 “D + 生态体系”,从单一产品设计拓展至产业链整合服务

三、深圳产品设计的核心竞争力

- 产业链优势:从设计、开模、元器件采购到量产,形成 48 小时响应圈

- 政策支持:政府推动 “设计之都” 建设,地方标准规范流程(如深圳市地方标准 DB4403/T 209-2021)

- 创新生态:毗邻香港的国际化视野 + 本土制造业根基,催生跨界融合设计

- 人才集聚:汇聚全国 70% 以上的工业设计人才,跨学科团队配置成为常态

结语

深圳产品设计流程的本质,是 “创意快速落地、价值精准传递” 的系统能力。其核心竞争力不仅在于设计本身,更在于将用户需求、技术创新、供应链效率与商业价值深度绑定的全链条整合能力。在 “中国制造 2025” 的背景下,深圳设计正从 “爆款打造” 向 “生态构建” 升级,成为全球硬件创新的核心引擎。

Standardization and Innovation Password of Shenzhen Product Design Process

NINEIDEA: As the “City of Design” and the global hardware manufacturing center, Shenzhen’s product design process integrates the full chain advantages of user insight, technological innovation, supply chain collaboration and commercial implementation. The following article will systematically break down the core process, methodology, and regional characteristics of product design in Shenzhen, and demonstrate its underlying logic of efficient iteration through benchmark cases:

1、 Process Overview: The Core Logic of Shenzhen Design

The core formula for product design in Shenzhen is “user value x business efficiency”, forming a closed-loop process of “insight design verification implementation iteration”. Different from traditional design patterns, its prominent advantages lie in:

Localized supply chain response (with an average sampling cycle 30% shorter than the industry)

Interdisciplinary collaborative design (industrial design+engineering technology+market operation)

Standardization system supported by policies (supporting local standard GB/T 33635-2017)

Data driven rapid iteration mechanism

2、 Detailed explanation of the six core process stages

(1) Requirement insight: The starting point of popular products is the real pain point

Core objective: To identify unmet needs from user scenarios and clarify product positioning

Shenzhen characteristic methodology:

Immersive scene research: For example, DESIGNDO captures potential needs by simulating home/office/outdoor scenes

User co creation mode: Type-C interface design of Nubia white charger, based on feedback from over 1200 users

Three dimensional verification system: market data (competitor analysis)+user feedback (questionnaire/interview)+technical feasibility (engineer pre review)

Output: User Profile Report, Requirement Priority Matrix, Technical Feasibility Assessment Form

(2) Scheme Design: Balancing Technology and Aesthetics

Core objective: Transform requirements into actionable design solutions that balance innovation and mass production

Key action:

Interdisciplinary integration: UAV design integrates electronic engineering (chip selection), mechanical structure (fuselage stability), and industrial design (aerodynamic appearance)

Modular architecture: The Aohai charging and discharging integrated gun adopts a gun box integrated structure, with replaceable components to reduce maintenance costs by 30%

Visual language definition: Combining brand tone and user preferences to output mood boards and color/material specifications

(3) Prototype validation: using iterations to reduce trial and error costs

Core objective: Verify design feasibility and user experience through rapid prototyping testing

Shenzhen Efficiency Password:

Agile development cycle: Adopting a “design test iteration” short cycle mode, DJI unmanned aerial vehicles optimize their body curves through 12 rounds of wind tunnel experiments

Digital twin technology: Virtual simulation testing replaces some physical prototypes, reducing development cycle by 40%

Multi dimensional review: internal cross departmental review (design+engineering+supply chain)+user testing (small-scale seed users)

Output: High fidelity prototype, test report, design modification checklist

(4) Supply chain implementation: closed-loop from drawings to products

Core advantage: Shenzhen has the most complete electronic hardware industry chain in the country, with an average distance of no more than 50 kilometers between design companies, mold factories, and material suppliers

Key action:

Localized collaboration: NINEIDEA design achieves 72 hour rapid customization of purple metal paint surface through local supply chain in the hair dryer project

Cost optimization: Standardized component procurement (such as Type-C interface universalization)+modular production, reducing Nubia charger costs by 25%

Mass production guarantee: pre production process review (DFM manufacturability design)+small batch trial production (50-100 pieces), and the mass production conversion rate of NINEIDEA design reached 92%

(5) Market Conversion: Empowering Business Value with Design

Core logic: Make design a carrier of brand communication, accurately reaching target users

Methodology:

Storytelling design: Children’s electric motorcycles retain the classic fuel tank shape, awakening brand sentiment

Accurate channel matching: Environmental protection products focus on social media (spreading environmental protection concepts), and innovative hardware prioritizes crowdfunding platforms (verifying the market)

Selling point extraction: Directly targeting core needs, such as “portable fast charging”, “silent design” and other concrete expressions

(6) Continuous iteration: long-term operation of popular products

Core objective: Based on market feedback, continuously optimize and build a product ecosystem

Key action:

Data driven optimization: Analyze sales data (such as Amazon review keywords) and user behavior data, iterate functionality

Intellectual Property Layout: Applying for appearance/structural patents, a company has provided design services to companies such as Huawei and Lenovo, obtaining over 3000 patents

Ecological Extension: ARtop Design expands from single product design to industry chain integration services through the “D+Ecological System”

3、 The core competitiveness of product design in Shenzhen

Industry chain advantage: From design, mold making, component procurement to mass production, forming a 48 hour response circle

Policy support: The government promotes the construction of the “City of Design” and local standards regulate processes (such as Shenzhen Local Standard DB4403/T 209-2021)

Innovation Ecology: International Perspective Adjacent to Hong Kong+Local Manufacturing Foundation, Generating Cross disciplinary Integration Design

Talent aggregation: Gathering over 70% of industrial design talents from across the country, interdisciplinary team configuration has become the norm

Conclusion

The essence of the product design process in Shenzhen is the systematic ability to quickly implement creativity and accurately convey value. Its core competitiveness lies not only in the design itself, but also in the full chain integration ability that deeply binds user needs, technological innovation, supply chain efficiency, and commercial value. Against the backdrop of “Made in China 2025”, Shenzhen Design is upgrading from “explosive product creation” to “ecological construction”, becoming the core engine of global hardware innovation.