NINEIDEA:ID设计师做产品设计最揪心的就是打样跟进,好比看着自己的设计 “孩子” 落地,初样可能像 “歪瓜裂枣”,全靠一步步掰扯修正。设计师第一次拿到 3D打印手板就懵了:图纸上的高级灰咋变成旧抹布色?后来才知道,打样讲究的是 “眼里有细节、沟通有干货、改样有策略”。

初样到手:先做 “三对照”

图纸和实物隔着无数 “默认选项”。我曾遇智能音箱网布颜色偏紫,只因工厂用了库存替代色。现在学乖了:

- 盯细节:用放大镜查 0.5mm 以上缝隙(比如手机壳合模线太粗会割手),侧光看曲面过渡是否自然;

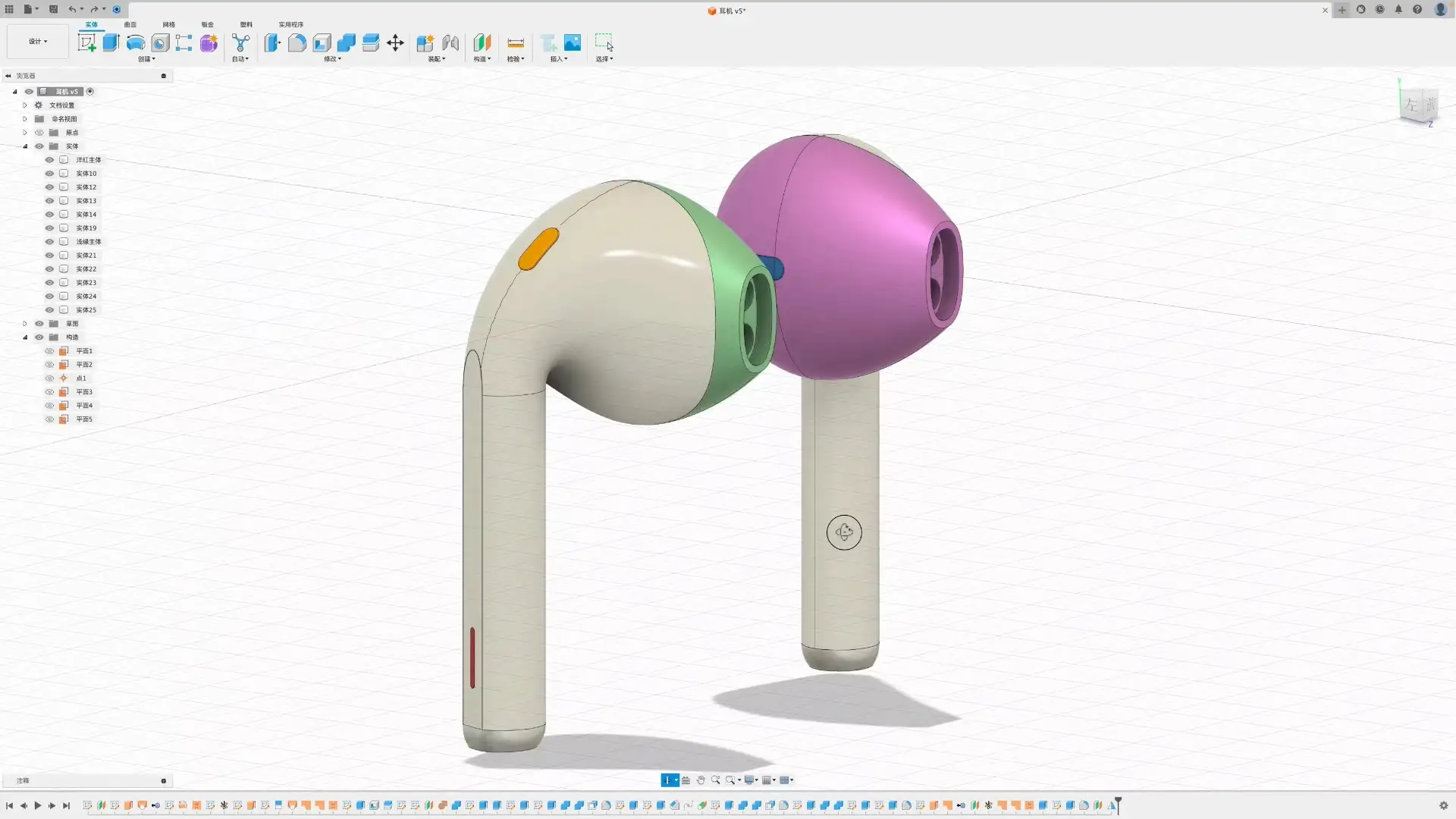

- 量尺寸:游标卡尺卡关键数据(耳机仓厚 1mm 就塞不进牛仔裤口袋),尤其人机接触部位(握把直径差 2mm 手感天差地别);

- 拍对比:初样和渲染图同框拍照,放大看颜色反光(金属喷砂太粗像砂纸,太细没质感)。

别空谈 “高级感”,带实物带参数

遇到问题别只说 “不对”,要像带儿童滑板车扶手改哑光面那次:直接拎来优质竞品,指着说 “ABS 加 30% 消光剂,模具温度从 80℃调到 75℃”,师傅秒懂。耳机外壳倒角太小剌手,工厂喊加钱?我当场用 3D 软件演示 “改 0.4mm 路径只多 2 分钟加工”,没多花一分钱 —— 专业细节才是沟通硬通货。

打样不是一次性考试,是 “迭代闯关”

好产品都是磨出来的,我做充电宝打了 7 次样:第三次 UV 烤漆太亮改半哑光 + 微纹理,第五次接口掉漆换 PVD 镀膜。每次改样都列 “问题清单”,记清解决了啥、新增啥风险(比如换材质可能超支 15%)。还要防 “隐性雷”:厨房小家电前几次外观没问题,第六次试产才发现高温下材料膨胀变形,最后拉工程师做应力测试才搞定。

量产前必问自己三个灵魂问题

样件顺眼了也别急签字:

- 用户场景覆盖没? 户外灯测过暴雨喷淋吗?婴儿餐盘边角弧度够不够(曾有家长投诉刮宝宝下巴);

- 供应链扛得住吗? 特殊贴纸会不会断货?渐变色喷涂工人能稳定操作吗(网红产品量产翻车多因工艺太复杂);

- 成本红线破了没? 进口磨砂料换国产,质感保 80%、成本降 40%—— 这才是该有的商业思维。

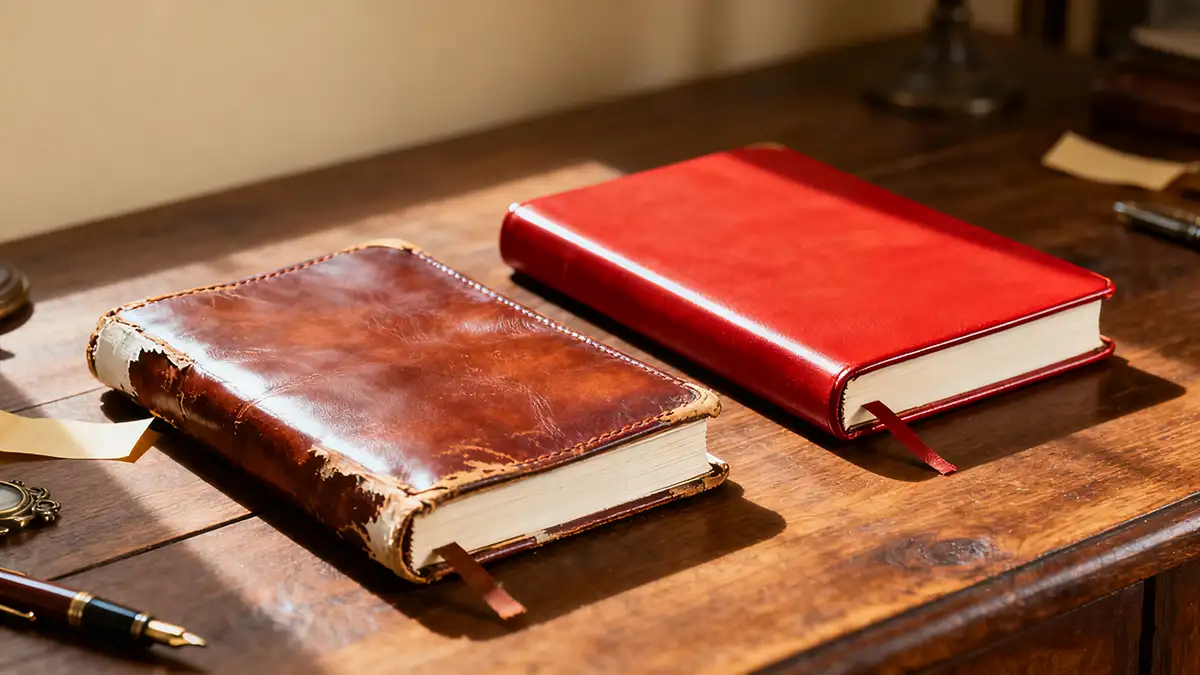

打样就像养孩子,图纸是蓝图,初样是学步,改样是矫正。设计师得蹲工厂、盯细节,在坚持和妥协间找平衡 —— 毕竟上架的产品不是完美图纸,而是颜值、体验、成本的平衡体。

Guide for ID designer to follow up on sample making and avoid pitfalls

NINEIDEA. The ID designer was confused when he received the 3D printing prototype for the first time: how did the high-end gray on the drawing turn into an old cloth color? Later on, I found out that the key to making samples is to have attention to detail, effective communication, and a strategic approach to sample improvement.

Get the initial sample: first do the “three comparisons”

There are countless’ default options’ between drawings and physical objects. I once encountered a smart speaker with a mesh color that was too purple, simply because the factory used stock to replace the color. I have learned my lesson now:

Pay attention to details: Use a magnifying glass to check for gaps of 0.5mm or more (such as cutting hands if the mold line of the phone case is too thick), and use a side light to check if the transition of the curved surface is natural;

Size measurement: Key data of the vernier caliper card (the headphone compartment cannot fit into the jeans pocket with a thickness of 1mm), especially in the human-machine contact area (the grip diameter difference is 2mm, and the feel is vastly different);

Take a comparison: Take a photo of the initial sample and rendered image in the same frame, zoom in to see the color reflection (metal sandblasting is too coarse like sandpaper, too fine without texture).

Don’t just talk about ‘high-end feeling’, bring physical objects with parameters

When encountering problems, don’t just say “no”, it’s like the time when you changed the matte finish of a children’s scooter armrest: just bring high-quality competitors and point at them, saying “ABS with 30% matting agent, mold temperature adjusted from 80 ℃ to 75 ℃”. The master understands in seconds. The chamfer of the earphone shell is too small and it’s irritating. Is the factory asking for extra money? I demonstrated on the spot with 3D software that ‘changing the 0.4mm path only takes 2 minutes for processing’, without spending a penny – professional details are the hard currency for communication.

Sample making is not a one-time exam, it is an iterative challenge

Good products are all polished out. I made 7 samples of power banks: the third time the UV paint was too bright and changed to semi matte with micro texture, and the fifth time the interface had paint peeling and replaced with PVD coating. Every time the sample is modified, a ‘problem list’ is made, clearly recording what has been solved and what risks have been added (such as the possibility of exceeding the budget by 15% due to material changes).

We also need to guard against “hidden lightning”: the appearance of kitchen appliances was fine a few times before, but it was only discovered during the sixth trial production that the material had expanded and deformed at high temperatures. Finally, the engineer conducted stress testing to solve the problem.

Three soul questions to ask oneself before mass production

Don’t rush to sign if the sample looks good:

Is the user scenario covered? Has the outdoor lamp measured rainstorm spray? Is the curvature of the corners of the baby tray sufficient (some parents have complained about scratching their baby’s chin);

Can the supply chain withstand it? Will special stickers be out of stock? Can gradient color spraying workers operate stably? (Many popular products in mass production may overturn due to complex processes);

Has the cost red line been broken? Replacing imported frosted materials with domestically produced ones ensures 80% quality and reduces costs by 40% – this is the business mindset that should be pursued.

Making a sample is like raising a child. The blueprint is the blueprint, the initial sample is for learning to walk, and modifying the sample is for correction. Designers have to squat in the factory, pay attention to details, and find a balance between persistence and compromise – after all, the products on the shelves are not perfect drawings, but a balance between appearance, experience, and cost.