NINEIDEA:深圳工业设计公司设计流程是一套系统且严谨的过程,以确保设计成果既满足市场需求,又兼具创新性与实用性。

1. 前期沟通与调研:

设计公司会与客户进行深入沟通,全面了解客户对产品的功能需求、目标用户群体、期望售价、品牌风格以及产品未来的发展方向等。与此同时,展开全方位的市场调研,分析同类产品的优缺点、市场占有率、消费者使用习惯和反馈,挖掘市场机会点,明确产品的竞争优势和独特卖点。此外,还会研究行业的技术发展趋势,确保设计的产品在技术上具有前瞻性和可行性。

2. 概念设计与创意阶段:

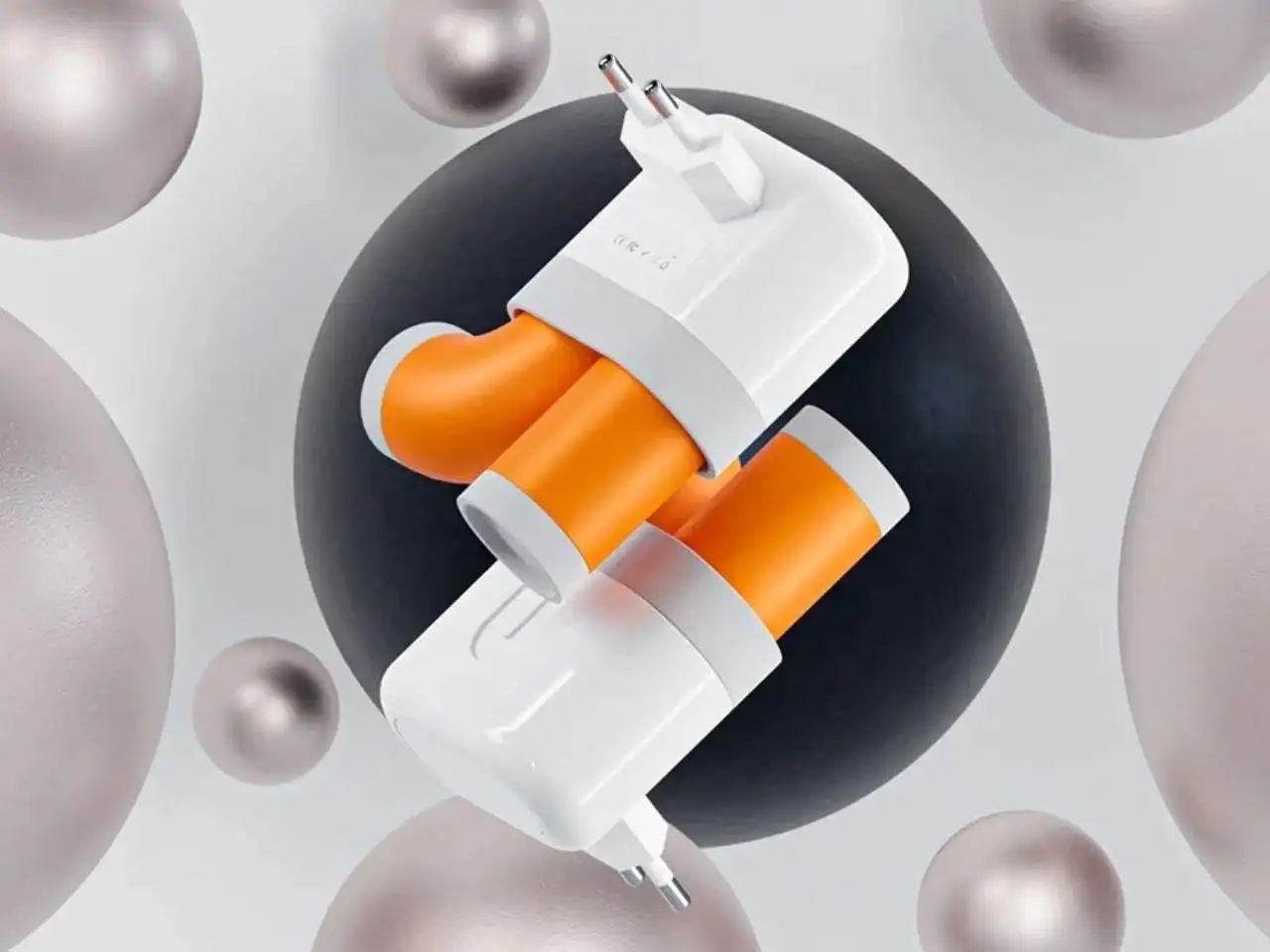

基于前期的调研结果,设计团队组织头脑风暴,激发成员的创意灵感,产生各种设计概念和想法。设计师们将这些概念以草图的形式呈现出来,快速记录不同的设计思路和形态,包括产品的整体造型、比例关系、细节特征等,初步确定产品的外观风格和大致轮廓。从众多草图中筛选出几个具有代表性和潜力的方案,制作成较为精细的效果图,利用专业软件为效果图添加材质、光影、色彩等细节,使其更接近真实产品效果,直观展示产品的外观特点,以便与客户进一步沟通和讨论。

3. 深化设计与确定方案:

在客户对效果图提出反馈意见后,设计师对方案进行优化和深化。精确绘制产品的三视图(正视图、侧视图、俯视图)和详细的尺寸图,标注准确的尺寸参数,为后续的结构设计和模具制造提供精确的数据支持。确定产品的色彩搭配、材质选择以及表面处理工艺,考虑色彩对用户心理的影响、材质的质感和性能、表面处理工艺的效果和成本等因素,以提升产品的整体品质和视觉效果。 与客户再次沟通,展示深化后的设计方案,充分交流并解答客户疑问,根据客户的最终意见确定最终设计方案。

4. 结构设计与手板制作:

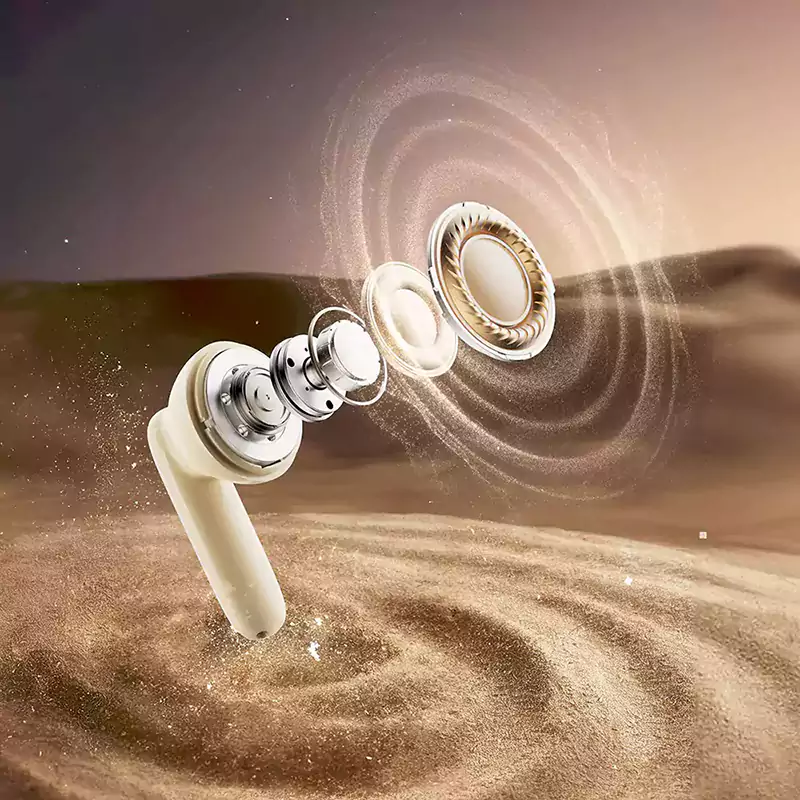

结构设计师依据确定的外观设计方案,进行产品内部结构的设计。考虑产品各部件的布局、连接方式、装配顺序、散热、强度、稳定性等因素,确保产品结构合理、功能实现顺畅且便于生产制造 。利用三维建模软件创建产品的结构模型,进行虚拟装配和干涉检查,提前发现并解决结构设计中可能存在的问题。根据结构设计图纸,制作产品的手板模型,选用合适的材料和加工工艺,精确复制产品的外观和结构。通过对手板模型的测试和评估,检查产品的尺寸精度、装配效果、功能实现情况等,发现问题及时进行调整和优化。

5. 模具设计与生产跟进:

手板模型验证通过后,进行模具设计。模具设计师根据产品的结构特点和生产要求,设计出合理的模具结构,包括模具的分型面、型芯、型腔、浇注系统、冷却系统等,确保模具能够高效、稳定地生产出符合质量要求的产品。在模具制造过程中,设计公司与模具制造商密切沟通协作,跟进模具制造进度,把控模具质量,及时解决制造过程中出现的问题。模具制造完成后,进行试模调试,对试模产品进行全面检测,根据检测结果对模具进行微调,直至生产出合格的产品。在产品批量生产阶段,设计公司可提供生产技术支持,协助客户解决生产过程中可能出现的与设计相关的问题,确保产品按照设计要求顺利生产 。

深圳工业设计公司设计流程表

| 阶段 | 核心内容 |

|---|---|

| 前期沟通与调研 | 明确客户需求,开展市场分析、竞品研究与技术趋势调研,挖掘产品机会点。 |

| 概念设计与创意 | 头脑风暴产出设计想法,绘制草图与精细效果图,初步确定产品外观风格与轮廓。 |

| 深化设计与定案 | 绘制三视图与尺寸图,敲定色彩、材质及表面工艺;与客户沟通后确定最终方案。 |

| 结构设计与手板 | 设计产品内部结构,完成三维建模与虚拟装配;制作手板模型并测试优化结构方案。 |

| 模具与生产跟进 | 设计模具结构并跟进制造,试模调试确保模具合格;提供生产阶段技术支持与问题解决。 |

Design Process of Shenzhen Industrial Design Company

NINEIDEA: The design process of Shenzhen Industrial Design Co., Ltd. is a systematic and rigorous process to ensure that the design results not only meet the market demand, but also be innovative and practical.

- Preliminary communication and research:

The design company will have in-depth communication with clients to comprehensively understand their functional requirements, target user groups, expected selling price, brand style, and future development direction of the product. At the same time, conduct comprehensive market research, analyze the advantages and disadvantages, market share, consumer usage habits, and feedback of similar products, explore market opportunities, and clarify the competitive advantages and unique selling points of the products. In addition, we will also study the technological development trends of the industry to ensure that the designed products are forward-looking and feasible in terms of technology.

- Conceptual design and creative stage:

Based on the previous research results, the design team organized brainstorming sessions to stimulate members’ creative inspiration and generate various design concepts and ideas. Designers present these concepts in the form of sketches, quickly recording different design ideas and forms, including the overall shape, proportion relationships, detailed features, etc. of the product, and preliminarily determining the appearance style and rough outline of the product.

Select several representative and potential solutions from numerous sketches, create more detailed renderings, and use professional software to add materials, light and shadow, color and other details to the renderings, making them closer to the real product effect and visually displaying the appearance characteristics of the product, in order to further communicate and discuss with customers.

- Deepen the design and determine the plan:

After receiving feedback from the client on the rendering, the designer optimized and deepened the plan. Accurately draw three views (front view, side view, top view) and detailed dimensional drawings of the product, label accurate dimensional parameters, and provide precise data support for subsequent structural design and mold manufacturing.

Determine the color matching, material selection, and surface treatment process of the product, considering the impact of color on user psychology, the texture and performance of materials, the effectiveness and cost of surface treatment processes, and other factors to enhance the overall quality and visual effect of the product. Communicate with the client again, present the deepened design plan, fully communicate and answer the client’s questions, and determine the final design plan based on the client’s final opinions.

- Structural design and prototype production:

The structural designer designs the internal structure of the product based on the determined exterior design scheme. Consider the layout, connection methods, assembly sequence, heat dissipation, strength, stability, and other factors of each component of the product to ensure a reasonable product structure, smooth functional implementation, and ease of production and manufacturing.

Create a structural model of the product using 3D modeling software, perform virtual assembly and interference inspection, and detect and solve potential problems in structural design in advance. Based on the structural design drawings, create a prototype model of the product, select appropriate materials and processing techniques, and accurately replicate the appearance and structure of the product. By testing and evaluating the prototype model, check the dimensional accuracy, assembly effect, and functional implementation of the product, and promptly adjust and optimize any problems found.

- Mold design and production follow-up:

After the prototype model is validated, proceed with mold design. Mold designers design a reasonable mold structure based on the structural characteristics and production requirements of the product, including the parting surface, core, cavity, pouring system, cooling system, etc., to ensure that the mold can efficiently and stably produce products that meet quality requirements. In the process of mold manufacturing, the design company closely communicates and collaborates with the mold manufacturer, follows up on the progress of mold manufacturing, controls mold quality, and promptly solves problems that arise during the manufacturing process.

After the mold manufacturing is completed, a trial mold debugging is carried out to comprehensively inspect the trial mold products. Based on the inspection results, the mold is fine tuned until a qualified product is produced. In the mass production stage of products, design companies can provide production technical support to assist customers in solving design related problems that may arise during the production process, ensuring smooth production of products according to design requirements.

Design Process Table of Shenzhen Industrial Design Company

| stage | core content |

|---|---|

| Pre communication and research | Clarify customer needs, conduct market analysis, competitor research, and technology trend research, and explore product opportunities. |

| Conceptual Design and Creativity | Brainstorm to generate design ideas, draw sketches and detailed renderings, and preliminarily determine the product’s appearance style and contour. |

| Deepening design and finalization | Draw three views and dimension diagrams, finalize colors, materials, and surface craftsmanship; Confirm the final plan after communicating with the client. |

| Structural Design and Prototype | Design the internal structure of the product, complete 3D modeling and virtual assembly; Create prototype models and test optimized structural solutions. |

| Mold and production follow-up | Design mold structure and follow up on manufacturing, trial mold debugging to ensure mold qualification; Provide technical support and problem-solving during the production phase. |