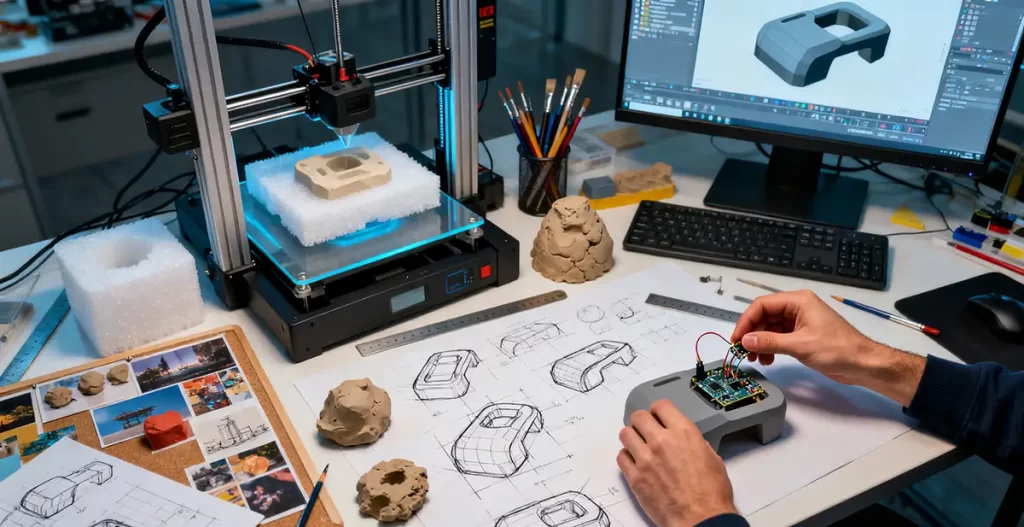

NINEIDEA:华强北的空气中永远弥漫着焊锡的气息。清晨七点半,第一批快递车开始装卸货物,穿着深色T恤的年轻创客蹲在柜台前,指着手机上CAD图纸和老板讨论结构开模。不远处,设计园区里,有人正将第三杯咖啡端到桌上,屏幕上是某个扫地机器人第27版曲面渲染图。这就是深圳工业设计模式——它从不始于宏大的宣言,而是藏在无数这样的细节里。

@NINEIDEA九号创新 www.nineidea.com

从“能用的”到“该有的”

十年前,深圳的代工厂老板们开始意识到一个问题:同样的主板、同样的传感器,韩国客户设计的空气净化器能卖到我们三倍的价格。那个被称为“设计”的东西,第一次从可有可无的装饰,变成了可以计算的商业价值。

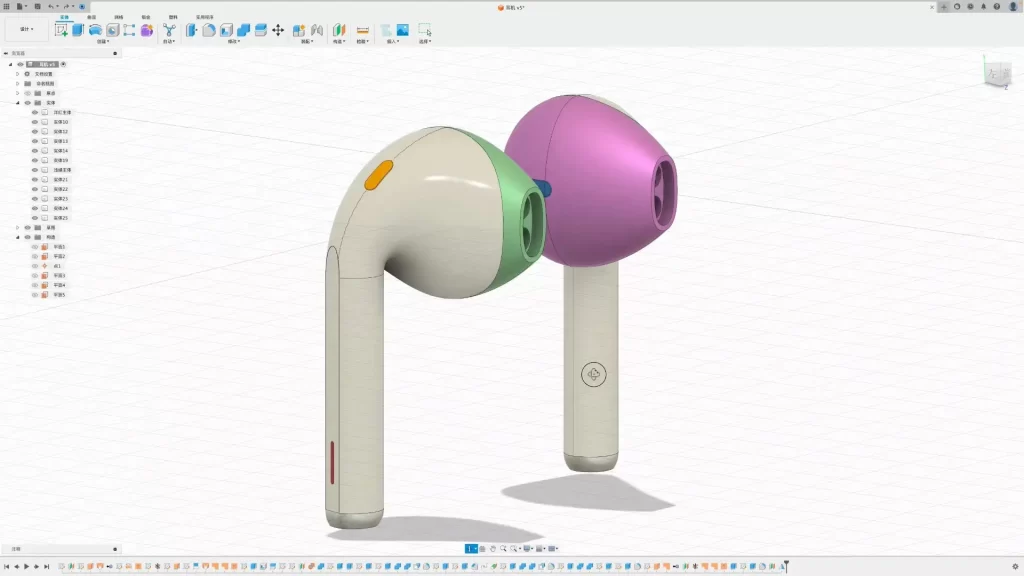

李工的工业设计工作室正好见证了这种转变。2014年,他们接到的需求八成是“给这个电路板做个壳”;现在,客户带着市场分析报告而来,第一句话往往是:“我们想定义下一代智能家居的交互方式。”

这种转变渗透在制造链的每个环节。宝安区的模具师傅老周能精准打出0.1毫米的渐变骨位——这是被无数设计稿“逼”出来的手艺。“以前图纸拿来,圆角一律R5,现在这些曲面啊,每个弧度都有说法。”他摸着刚试模的智能音箱外壳,光线下表面呈现出细腻的织物质感,“就这个纹理,开了七套电极。”

密度造就的魔力

深圳工业设计的独特竞争力,或许可以用“三个半小时”概括:从提出修改方案,到找到专业工程师,到看见新打的样品,只需要这么长时间。这种密度催生了特殊的协作方式。

下午三点,科技园某栋写字楼里,硬件工程师、UI设计师和结构工程师正围着3D打印的智能手表原型激烈讨论。结构工程师突然起身:“这个防水结构有问题,我拿去西乡找张工当面看。”一小时后,修改后的图纸已经发到龙华的快速模具厂。

这种效率不是某个企业的专利,而是整座城市形成的生态系统。当你需要一种特殊的金属涂层,总有人在观澜的工厂能实现;当你对CMF(颜色、材料、工艺)有特殊要求,第二天就能在材料市场找到十种样品。

在约束中创造

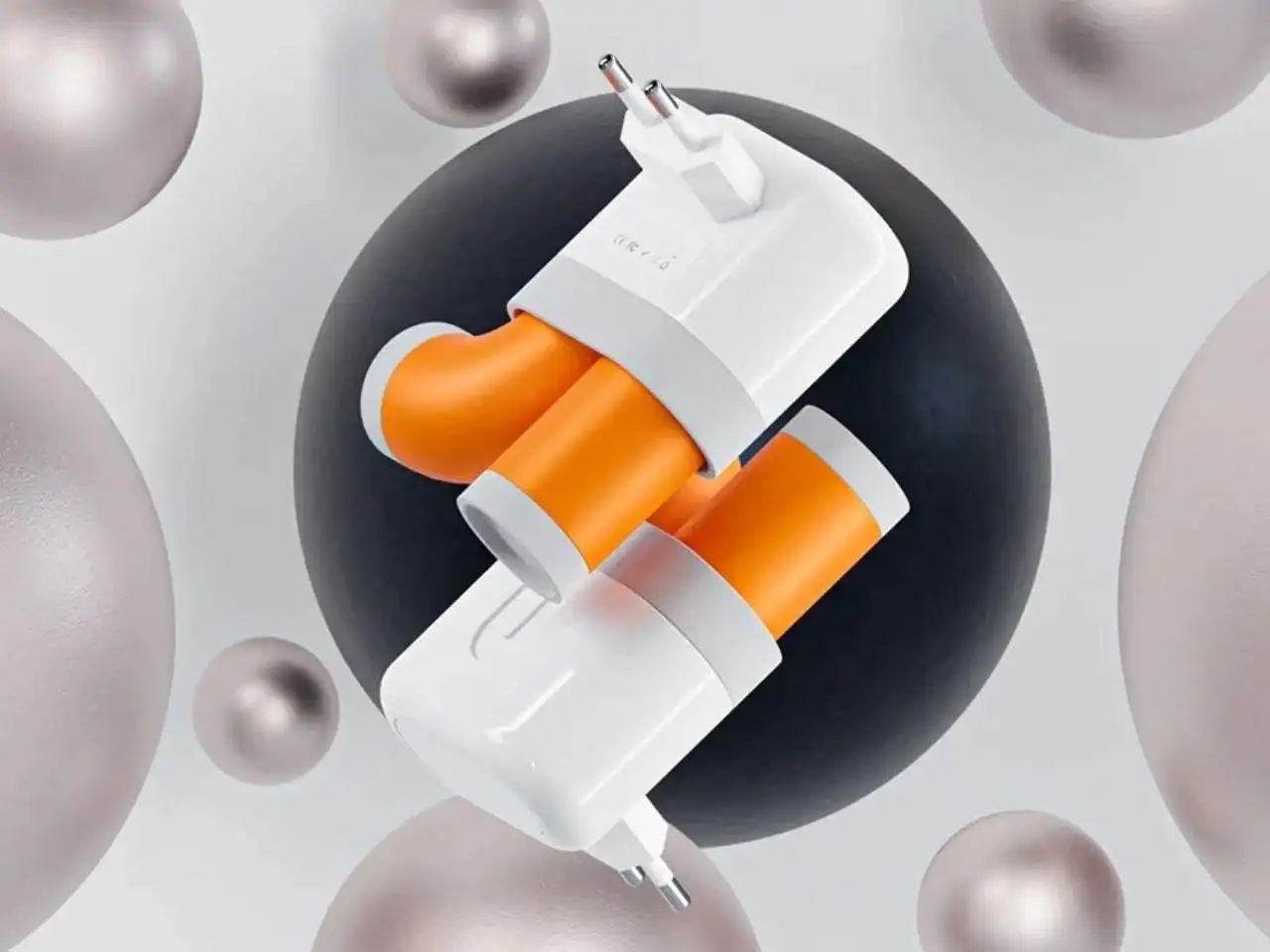

所有深圳工业设计师都懂得一个真理:最美的曲线不是贝塞尔曲线,而是可生产、可组装、可维修的曲线。

这造就了这里独特的设计哲学——在无数约束中寻找最优解。某个智能家居项目的负责人展示了他们的设计历程:最初的概念天马行空,像科幻电影里的道具;经过十二轮修改,最终产品简洁优雅,每一个弧度的背后都是与结构、散热、天线性能的艰难妥协。

“好的设计不是自说自话的艺术品,”他说,“而是在成本、技术、用户体验之间找到的那个完美平衡点。”

这种务实精神延伸到了每个细节。他们为儿童智能手表设计的表带,既要柔软亲肤,又要通过严格的拉力测试;每个充电触点的位置,都经过上百次插拔实验。“设计师的浪漫?”他笑了,“是让你的设计能顺利地从生产线走下来,进入千家万户。”

下一个十年

夜幕降临,深圳湾的人才公园亮起灯光。一群刚结束头脑风暴的年轻设计师在草坪上休息,谈论着AI将如何改变设计流程,讨论着可持续发展材料的最新进展。

他们中有人来自东北,有人来自四川,被这座城市的设计生态吸引而来。就像上世纪八十年代的硅谷,今天的深圳用一种独特的魅力,汇聚着渴望创造的人们。

不远处,大疆总部大楼像一架准备起飞的无人机,柔光从无数精心设计的缝隙中透出。这或许是深圳工业设计最好的隐喻——它扎根于坚实的制造土壤,却始终望向创新的天空。

在这里,每个想法都有机会变成现实,每个微小的改进都在重新定义“中国制造”的含义。从模仿到创新,从制造到创造,深圳工业设计正在完成的,不仅仅是一座城市的转型,更是一种创造方式的革命。

当明天的太阳升起,又会有新的创意在华强北诞生,在宝安的工厂里试产,在南山的设计室里打磨。这就是深圳——在电路板与梦想之间,它永远选择两者都要。

Shenzhen Industrial Design Pattern: Creating within Constraints

NINEIDEA: The air of Huaqiang North is always filled with the smell of soldering tin. At 7:30 in the morning, the first batch of express delivery trucks began loading and unloading goods. A young maker wearing a dark T-shirt crouched in front of the counter, pointing to the CAD drawings on his phone and discussing structural mold making with the boss. Not far away, in the design park, someone is holding the third cup of coffee on the table, and on the screen is a rendering of the 27th version of a robotic vacuum cleaner. This is the Shenzhen industrial design pattern – it never starts with grand declarations, but is hidden in countless such details.

From ‘usable’ to ‘what should be’

Ten years ago, the bosses of OEM factories in Shenzhen began to realize a problem: air purifiers designed by Korean customers could be sold for three times our price with the same motherboard and sensors. That thing known as’ design ‘, for the first time, has transformed from an optional decoration to a measurable commercial value.

Li Gong’s industrial design studio happened to witness this transformation. In 2014, 80% of the demands they received were for “making a shell for this circuit board”; Nowadays, when customers come with market analysis reports, the first sentence is often: “We want to define the interaction mode of the next generation of smart homes

This transformation permeates every link in the manufacturing chain. Mold master Lao Zhou from Bao’an District is able to accurately create 0.1mm gradient bone positions – a skill that has been forced out by countless design drafts. Previously, when the drawings were taken, the rounded corners were all R5, but now these surfaces have their own specifications for each curvature. ”He touched the shell of the newly tested smart speaker, and under the light, the surface showed a delicate texture. “With this texture, seven sets of electrodes were used,” he said

The magic created by density

The unique competitiveness of Shenzhen’s industrial design can perhaps be summarized as “three and a half hours”: from proposing modification plans, to finding professional engineers, to seeing newly made samples, it only takes this long time. This density has given rise to special ways of collaboration.

At 3 pm, in an office building in the technology park, hardware engineers, UI designers, and structural engineers were engaged in a heated discussion around a 3D printed prototype of a smartwatch. The structural engineer suddenly stood up and said, “There is a problem with this waterproof structure. I will take it to Xixiang to see Mr. Zhang face to face.” One hour later, the revised drawings had been sent to the rapid mold factory in Longhua.

This efficiency is not exclusive to a single enterprise, but rather an ecosystem formed by the entire city. When you need a special metal coating, there is always someone at Guanlan’s factory who can achieve it; When you have special requirements for CMF (color, material, process), you can find ten samples in the material market the next day.

Create within constraints

All industrial designers in Shenzhen understand a truth: the most beautiful curve is not a Bezier curve, but a curve that can be produced, assembled, and repaired.

This has created a unique design philosophy here – finding the optimal solution among countless constraints. The person in charge of a smart home project showcased their design process: the initial concept was imaginative, like props in science fiction movies; After twelve rounds of modifications, the final product is simple and elegant, with every curve representing a difficult compromise with structure, heat dissipation, and antenna performance.

Good design is not a self proclaimed work of art, “he said,” but the perfect balance found between cost, technology, and user experience

This pragmatic spirit extends to every detail. The strap they designed for children’s smartwatches must be soft and skin friendly, as well as undergo strict tensile testing; The position of each charging contact has undergone hundreds of insertion and extraction experiments. The romance of a designer? “He smiled.” It’s about making your design smoothly go down the production line and into thousands of households

the next decade

As night falls, the Talent Park in Shenzhen Bay lights up. A group of young designers who have just finished brainstorming are resting on the lawn, discussing how AI will change the design process and the latest developments in sustainable materials.

Some of them come from Northeast China, while others come from Sichuan, attracted by the design ecology of this city. Just like Silicon Valley in the 1980s, Shenzhen today gathers people who aspire to create with a unique charm.

Not far away, the headquarters building of DJI is like a drone preparing to take off, with soft light shining through countless carefully designed gaps. This may be the best metaphor for Shenzhen’s industrial design – it is rooted in solid manufacturing soil, but always looks towards the sky of innovation.

Here, every idea has the opportunity to become a reality, and every small improvement is redefining the meaning of ‘Made in China’. From imitation to innovation, from manufacturing to creation, what Shenzhen’s industrial design is completing is not only the transformation of a city, but also a revolution in the way of creation.

When the sun rises tomorrow, new ideas will be born in Huaqiangbei, tested in factories in Bao’an, and polished in design studios in Nanshan. This is Shenzhen – between circuit boards and dreams, it always chooses both.