NINEIDEA:工业设计远不止是让产品变得好看。它是一个严谨的、以用户为中心的系统性创新过程,核心使命是将模糊的用户需求转化为具有市场竞争力且可商业化的实体产品。这条从洞察到落地的路径,决定了产品的成败。本文将系统性地拆解这一过程,揭示优秀工业设计背后的逻辑。

第一阶段:深度用户洞察——挖掘“冰山之下”的需求

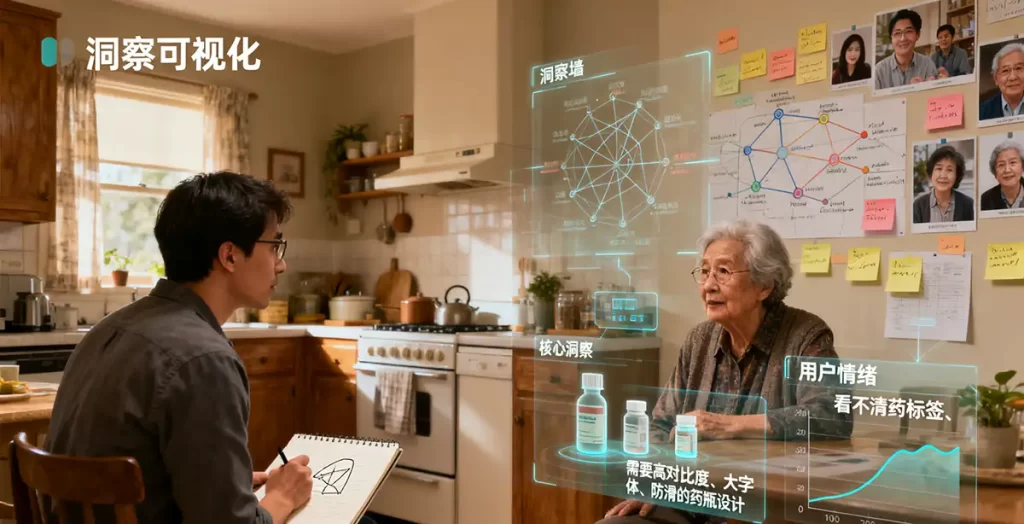

一切伟大设计的起点,都是深刻的用户理解。这一阶段的目标是超越表面需求,探寻用户未言明的、甚至自己都未意识到的真实痛点与渴望。

- 方法多元融合: 设计师综合运用 ethnographic research(田野调查)、深度访谈、情境观察、用户旅程地图等方法,沉浸到用户的真实使用环境中。他们关注的不仅是“用户说什么”,更是“用户做什么”以及“为什么这么做”。

- 从数据到洞察: 收集到的海量信息(如访谈记录、行为视频、照片)是原始数据。设计师通过亲和图、痛点分析等工具,对其进行聚类、归纳,提炼出关键的用户洞察(Insight)。例如,一个洞察可能是:“独居的年轻人在厨房做饭时,强烈的孤独感让他们更倾向于使用手机边看视频边操作,而非专注于烹饪本身。” 这个洞察远比“需要一个更亮的炉灶”更具启发性和设计价值。

此阶段的产出物是清晰的设计机会点(Design Opportunity)和设计指导原则(Design Guideline),为后续的创新指明方向。

第二阶段:创意转化与概念设计——将洞察“翻译”为解决方案

有了深刻的洞察,下一步是将抽象的需求转化为具体的产品概念。这是想象力与逻辑碰撞的阶段。

- 头脑风暴与草图发散: 设计师进行无拘无束的创意发散,通过大量手绘草图、故事板等形式,探索各种可能的解决方案。数量优于质量,目标是尽可能覆盖更广的可能性。

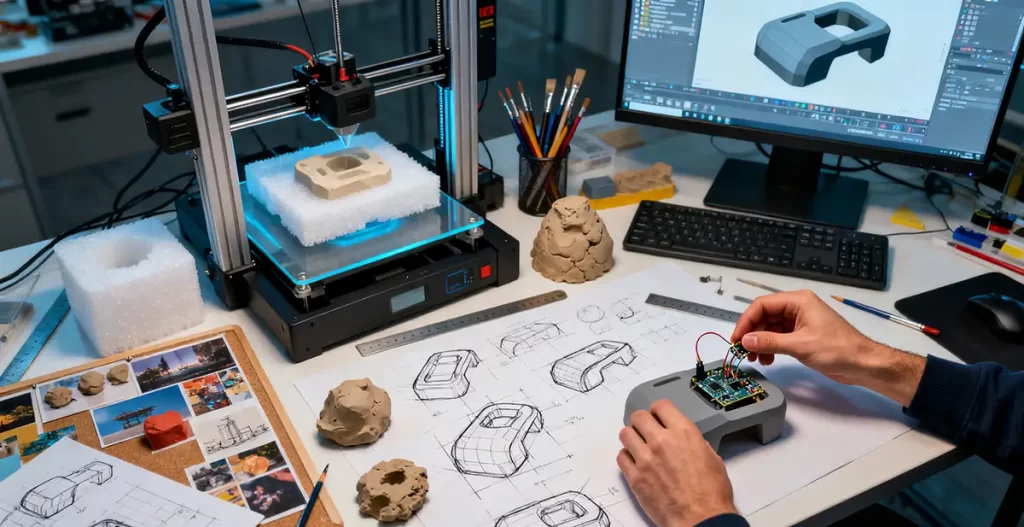

- 概念收敛与原型验证: 从海量创意中筛选出几个最有潜力的方向,进行深化。此时,快速原型(Rapid Prototyping)变得至关重要。无论是用泡沫、3D打印还是纸板制作的粗糙原型,都能让设计团队和用户尽早地、低成本地体验和测试概念。通过用户的真实反馈,概念被不断迭代、优化,最终聚焦到1-2个最优方案。

此阶段的核心是循环式的“制作-测试-学习”(Build-Measure-Learn),确保设计方向始终与用户需求紧密对齐。

第三阶段:工程实现与生产准备——让创意“脚踏实地”

一个完美的概念若无法被制造出来,便毫无价值。此阶段,工业设计师需要与工程师、供应链专家紧密协作,将设计概念“工程化”。

- 细节深化与DFX: 设计师需要深入每个细节:CMF(色彩、材料、工艺)的选定、零件之间的装配方式、分模线的位置、表面处理等。同时,必须遵循DFM(可制造性设计)、DFA(可装配性设计)等原则,确保产品能被高效、低成本、高质量地生产出来。

- 技术整合: 将电机、电路板、传感器等内部元件巧妙地整合进有限的外壳空间中,并处理好散热、强度、电磁兼容等问题。优秀的设计是在美学、人机工程学和工程约束之间找到最佳平衡。

此阶段的产出物是一套完整的、可用于开模生产的3D工程数据、CMF方案册和产品外观手板。

第四阶段:商业落地与市场创造——从产品到商品

产品走下生产线,设计的使命并未结束,而是进入了最终的商业价值验证环节。

- 包装与用户体验: 设计师负责设计开箱体验,确保产品从包装盒中取出那一刻起,就能传递品牌价值,并让用户能直观地开始使用。

- 成本控制与定价策略: 前期设计的决策直接决定了产品的BOM成本。设计团队需要与市场、财务部门协同,确保产品在目标价格区间内具备竞争力。

- 市场传播与品牌建设: 产品的视觉形象本身就是最有力的广告。一个具有辨识度的好设计,能降低营销成本,提升品牌美誉度,并最终转化为市场份额和用户忠诚度。

商业成功的最终标志是产品实现了预期的商业目标——无论是销售额、市场份额、用户增长还是品牌提升。一个成功的工业设计,正是这一价值链条的催化剂和连接器。

工业设计是一个贯穿始终的战略性工具。它始于对人性的深刻共情,经由严谨的创意与工程转化,最终落脚于切实的商业价值。在竞争日益激烈的市场环境中,企业若能真正理解并善用这条“从用户洞察到商业落地”的全链路设计思维,就能创造出不仅满足用户、更能引领市场的爆款产品,从而构筑起坚固的品牌护城河。

@NINEIDEA九号创新 www.nineidea.com

From Insight to Value: Excellent Industrial Design Builds a Bridge between User Needs and Business Success

NINEIDEA: Industrial design is more than just making products look good. It is a rigorous, user centered systematic innovation process, with the core mission of transforming vague user needs into competitive and commercially viable physical products. This path from insight to implementation determines the success or failure of the product. This article will systematically break down this process and reveal the logic behind excellent industrial design.

Phase 1: Deep User Insights – Digging into the Needs Underneath the Iceberg

The starting point of all great designs is profound user understanding. The goal of this stage is to go beyond surface needs and explore the real pain points and desires that users have not expressed or even realized.

Diversified integration of methods: Designers comprehensively use ethnographic research, in-depth interviews, situational observations, user journey maps, and other methods to immerse themselves in the user’s real usage environment. They are not only concerned with ‘what users say’, but also with ‘what users do’ and ‘why they do it’.

From data to insights: The massive amount of information collected (such as interview records, behavioral videos, photos) is raw data. Designers use tools such as affinity maps and pain point analysis to cluster and summarize them, extracting key user insights. For example, an insight may be: “The strong sense of loneliness experienced by young people living alone in the kitchen makes them more inclined to use their phones to watch videos while cooking, rather than focusing on the cooking itself.” This insight is far more inspiring and valuable in design than “needing a brighter stove.

The output of this stage is clear design opportunities and design guidelines, which provide direction for subsequent innovation.

Phase 2: Creative Transformation and Conceptual Design – Translating Insights into Solutions

With profound insights, the next step is to transform abstract requirements into concrete product concepts. This is the stage of collision between imagination and logic.

Brainstorming and Sketch Divergence: Designers engage in unrestrained creative divergence, exploring various possible solutions through a large number of hand drawn sketches, storyboards, and other forms. Quantity is superior to quality, with the goal of covering as wide a range of possibilities as possible.

Concept convergence and prototype validation: Select several most promising directions from a massive amount of creativity and deepen them. At this point, rapid prototyping becomes crucial. No matter the rough prototype is made of foam, 3D printing or cardboard, it can enable the design team and users to experience and test the concept as soon as possible and at a low cost. Through user feedback, the concept is continuously iterated and optimized, ultimately focusing on 1-2 optimal solutions.

The core of this stage is a cyclical “Build Measure Learn” process, ensuring that the design direction is always closely aligned with user needs.

Phase Three: Engineering Implementation and Production Preparation – Keeping Creativity grounded

A perfect concept is worthless if it cannot be created. At this stage, industrial designers need to work closely with engineers and supply chain experts to “engineer” design concepts.

Detail deepening and DFX: Designers need to delve into every detail: the selection of CMF (color, material, process), the assembly method between parts, the position of parting lines, surface treatment, etc. At the same time, it is necessary to follow principles such as DFM (Design for Manufacturing) and DFA (Design for Assembly) to ensure that products can be produced efficiently, at low cost, and with high quality.

Technical integration: Cleverly integrate internal components such as motors, circuit boards, sensors, etc. into a limited housing space, and handle issues such as heat dissipation, strength, and electromagnetic compatibility. Excellent design is finding the best balance between aesthetics, ergonomics, and engineering constraints.

The output of this stage is a complete set of 3D engineering data, CMF solution book, and product appearance prototype that can be used for mold production.

Stage Four: Commercial Landing and Market Creation – From Product to Commodity

When the product goes off the production line, the mission of design has not ended, but has entered the final stage of commercial value verification.

Packaging and User Experience: Designers are responsible for designing the unboxing experience, ensuring that the brand value is conveyed from the moment the product is removed from the packaging box, and allowing users to start using it intuitively.

Cost control and pricing strategy: The decisions made in the early stages of design directly determine the BOM cost of the product. The design team needs to collaborate with the marketing and finance departments to ensure that the product is competitive within the target price range.

Market communication and brand building: The visual image of a product itself is the most powerful advertisement. A well recognizable design can reduce marketing costs, enhance brand reputation, and ultimately translate into market share and user loyalty.

The ultimate sign of business success is that the product achieves the expected business goals – whether it is sales, market share, user growth, or brand enhancement. A successful industrial design is the catalyst and connector of this value chain.

Industrial design is a strategic tool that runs through the entire process. It begins with a profound empathy for human nature, goes through rigorous creative and engineering transformations, and ultimately ends up with tangible commercial value. In an increasingly competitive market environment, if enterprises can truly understand and make good use of the full chain design thinking from user insights to business implementation, they can create popular products that not only meet users but also lead the market, thus building a strong brand moat.

@NINEIDEA九号创新 www.nineidea.com