NINEIDEA:在当今数字化时代,充电宝已成为人们日常生活中不可或缺的电子产品。一款优秀充电宝的诞生,需要经过严谨且系统化的设计开发流程。从前期调研到最终量产上市,每个环节都至关重要,下面为你详细解析充电宝设计开发流程。

一、市场调研与需求分析

市场调研是充电宝设计开发的第一步,通过收集行业报告、分析市场趋势,了解当前充电宝市场的规模、竞争格局以及消费者偏好。同时,开展用户调研,采用问卷调查、焦点小组访谈等方式,收集消费者对充电宝容量、外观、充电速度、便携性等方面的需求与痛点。此外,还需关注竞争对手的产品特点、价格策略、营销方式,找出市场空白点和差异化竞争方向,为产品定位提供依据。

二、产品定义与概念设计

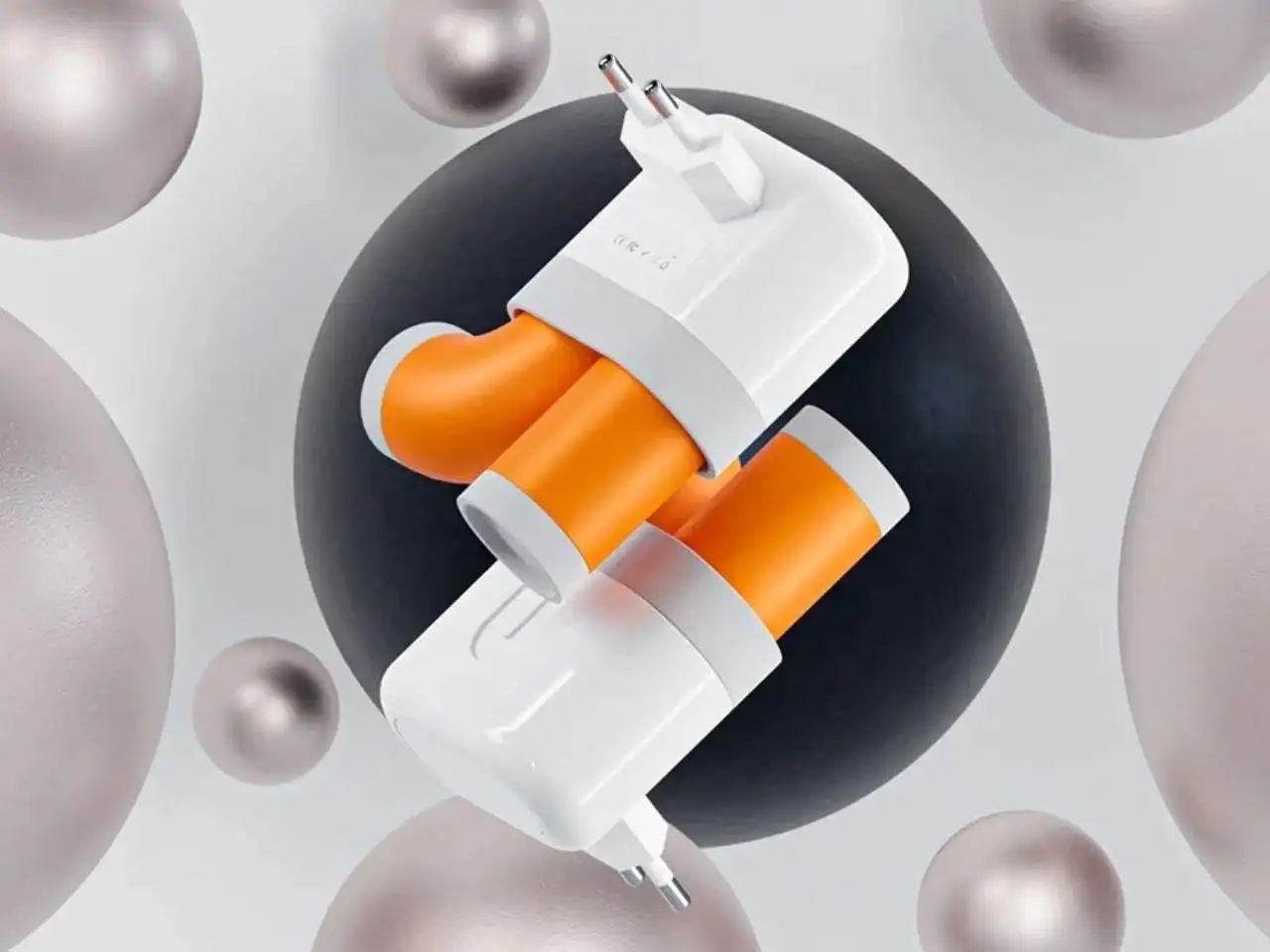

基于市场调研结果,明确充电宝的目标用户群体、核心功能、产品定位和价格区间,形成详细的产品需求文档。接着,进行概念设计,设计师团队根据产品定位和目标用户喜好,构思产品的外观风格、色彩搭配、材质选择等。可以通过手绘草图、数字建模等方式,将创意转化为初步的设计方案,为后续开发提供方向。

三、硬件方案设计

硬件方案设计是确保充电宝性能的关键环节。首先,确定电芯类型和容量,常见的电芯有锂离子电池和锂聚合物电池,需根据产品定位和成本要求选择合适的电芯,并计算所需容量以满足用户使用需求。然后,设计充电电路,包括输入充电模块、输出放电模块、过充过放保护电路、短路保护电路等,确保充电过程安全、高效。同时,规划接口类型,如常见的 USB – C、USB – A、无线充电等,满足不同设备的充电需求。此外,还需考虑电路板布局,合理规划各电子元件的位置,减少电磁干扰,提高电路稳定性。

四、结构设计与手板制作

结构设计要兼顾产品的功能性、可靠性和外观要求。设计师需设计外壳的形状、尺寸、材质,确保内部元件合理布局,同时满足散热、防水、防尘等要求。在设计过程中,利用三维建模软件进行结构建模,通过模拟分析验证结构的合理性和强度。完成结构设计后,制作手板模型,通常采用 3D 打印或 CNC 加工等方式,将设计方案转化为实物模型,以便直观地评估产品的外观、尺寸、装配工艺等,发现问题及时调整优化。

五、软件与功能开发(如有)

若充电宝具备智能功能,如电量显示、充电模式切换、APP 控制等,则需要进行软件与功能开发。软件工程师编写相应的程序代码,实现各项功能,并与硬件进行联调测试,确保软件与硬件协同工作,功能稳定可靠。

六、测试与验证

测试与验证是确保产品质量的重要环节。首先进行性能测试,包括充电速度测试、放电容量测试、转换效率测试等,评估充电宝的各项性能指标是否达到设计要求。接着进行安全测试,如过充过放保护测试、短路保护测试、耐高温耐低温测试、跌落测试等,确保产品在各种使用场景下的安全性。此外,还需进行可靠性测试,模拟产品在长期使用过程中的性能变化,验证产品的使用寿命。对于测试中发现的问题,及时进行整改优化,直至产品各项指标符合要求。

七、优化与量产准备

根据测试结果,对产品进行全面优化,包括硬件电路的微调、结构设计的改进、软件功能的完善等。同时,确定生产工艺和流程,选择合适的原材料供应商和生产厂家,制定生产计划和质量控制方案,为量产做好充分准备。

八、量产与上市

完成量产准备后,进入正式生产阶段,严格按照生产工艺和质量控制标准进行生产,确保产品质量的一致性和稳定性。产品生产完成后,进行包装设计和品牌营销策划,通过线上线下渠道进行产品推广销售,将充电宝推向市场,满足消费者需求。

Detailed explanation of the design and development process for power banks

NINEIDEA: In today’s digital era, power bank has become an indispensable electronic product in people’s daily life. The birth of an excellent power bank requires a rigorous and systematic design and development process. From preliminary research to final mass production and launch, every step is crucial. Below is a detailed analysis of the design and development process for power banks.

1、 Market research and demand analysis

Market research is the first step in the design and development of power banks. By collecting industry reports and analyzing market trends, we can understand the current size, competitive landscape, and consumer preferences of the power bank market. At the same time, user research will be conducted using methods such as questionnaire surveys and focus group interviews to collect consumers’ needs and pain points regarding the capacity, appearance, charging speed, portability, and other aspects of power banks. In addition, it is necessary to pay attention to the product characteristics, pricing strategies, and marketing methods of competitors, identify market gaps and differentiated competition directions, and provide a basis for product positioning.

2、 Product Definition and Conceptual Design

Based on market research results, clarify the target user group, core functions, product positioning, and price range of power banks, and form a detailed product demand document. Next, conceptual design is carried out, and the design team conceptualizes the appearance style, color matching, material selection, etc. of the product based on its positioning and target user preferences. Creativity can be transformed into preliminary design proposals through hand drawn sketches, digital modeling, and other methods, providing direction for subsequent development.

3、 Hardware scheme design

The design of hardware scheme is a key link to ensure the performance of the power bank. Firstly, determine the type and capacity of the battery cell. Common battery cells include lithium-ion batteries and lithium polymer batteries. It is necessary to choose the appropriate battery cell based on product positioning and cost requirements, and calculate the required capacity to meet user needs. Then, design the charging circuit, including input charging module, output discharging module, overcharge and over discharge protection circuit, short circuit protection circuit, etc., to ensure the safe and efficient charging process.

At the same time, plan interface types such as common USB-C, USB-A, wireless charging, etc. to meet the charging needs of different devices. In addition, it is necessary to consider the layout of the circuit board, plan the position of each electronic component reasonably, reduce electromagnetic interference, and improve circuit stability.

4、 Structural Design and Prototype Manufacturing

Structural design should take into account the functionality, reliability, and appearance requirements of the product. Designers need to design the shape, size, and material of the casing to ensure a reasonable layout of internal components while meeting requirements for heat dissipation, waterproofing, and dust prevention. During the design process, 3D modeling software is used for structural modeling, and the rationality and strength of the structure are verified through simulation analysis.

After completing the structural design, a prototype model is made, usually using methods such as 3D printing or CNC machining to convert the design scheme into a physical model, in order to intuitively evaluate the appearance, size, assembly process, etc. of the product, and to promptly adjust and optimize any problems found.

5、 Software and feature development (if any)

If the power bank has intelligent functions such as battery level display, charging mode switching, APP control, etc., software and function development is required. Software engineers write corresponding program code to implement various functions, and conduct joint debugging and testing with hardware to ensure that software and hardware work together and function stably and reliably.

6、 Testing and Validation

Testing and validation are important steps in ensuring product quality. Firstly, perform performance testing, including charging speed testing, discharge capacity testing, conversion efficiency testing, etc., to evaluate whether the various performance indicators of the power bank meet the design requirements. Continuing with safety testing, such as overcharge and over discharge protection testing, short circuit protection testing, high and low temperature resistance testing, drop testing, etc., to ensure the safety of the product in various usage scenarios. In addition, reliability testing is required to simulate the performance changes of the product during long-term use and verify its service life. For problems discovered during testing, timely rectification and optimization should be carried out until all product indicators meet the requirements.

7、 Optimization and mass production preparation

Based on the test results, the product will be comprehensively optimized, including fine-tuning of hardware circuits, improvement of structural design, and enhancement of software functionality. At the same time, determine the production process and procedures, select suitable raw material suppliers and manufacturers, develop production plans and quality control schemes, and make sufficient preparations for mass production.

8、 Mass production and market launch

After completing the mass production preparation, enter the formal production stage and strictly follow the production process and quality control standards to ensure the consistency and stability of product quality. After the production of the product is completed, packaging design and brand marketing planning are carried out, and the product is promoted and sold through online and offline channels to bring the power bank to the market and meet consumer needs.