NINEIDEA:企业设立独立的CMF工业设计岗位,本质是应对消费升级、市场竞争与产业复杂度提升的必然选择。这一岗位的独立,背后是 CMF (色彩、材料、表面处理)从 “设计附属环节” 升级为 “产品核心竞争力载体” 的逻辑转变。

消费需求从 “功能满足” 转向 “体验溢价”,CMF 成为情感连接的核心载体

当代用户对产品的期待早已超越 “能用”,更追求 “有感”—— 视觉的愉悦、触觉的舒适、甚至材料传递的文化符号(如 “侘寂风” 的微水泥质感、国潮的朱砂红)。而 CMF 是直接触达用户感官的 “第一语言”:

例如,年轻人对 “治愈系” 家电的偏好,依赖 CMF 通过 “奶白 + 磨砂 ABS” 传递 “温柔感”;

高端用户对 “奢华感” 的追求,需要 CMF 用 “哑光金属 + 纳米涂层” 替代传统电镀(更环保且质感更细腻)。

这些体验的精准落地,需要专人深耕用户感官偏好、文化趋势(如潘通年度色、小红书流行材质),而非工业设计师兼顾 —— 后者更聚焦形态与功能,难以深入研究 “不同色温的白如何影响睡眠”“0.1mm 的纹理深度对触感的差异” 等细节。

市场同质化严重,CMF 成为差异化竞争的 “低成本突破口”

在技术迭代放缓、产品形态趋同的行业(如 3C、家电、汽车),CMF 是最容易形成记忆点的差异化路径。例如:

手机行业,当硬件参数差异缩小时,华为 Mate 系列的 “素皮后盖”(材料创新)、OPPO 的 “流光晶钻工艺”(表面处理)成为核心卖点;

家电行业,小米的 “白色极简 + 阳极氧化铝” 与美的的 “莫兰迪色系 + 哑光搪瓷”,通过 CMF 区隔出 “年轻科技” 与 “家居融合” 的不同定位。

这种差异化需要专人持续跟踪新材料(如生物基塑料、石墨烯涂层)、新工艺(如激光微雕、磁控溅射),并将其转化为可落地的设计语言 —— 若由工业设计师兼顾,往往因精力分散导致 “跟风模仿” 而非 “创新突破”。

供应链与工艺复杂度飙升,需专人打通 “设计 – 量产” 的落地壁垒

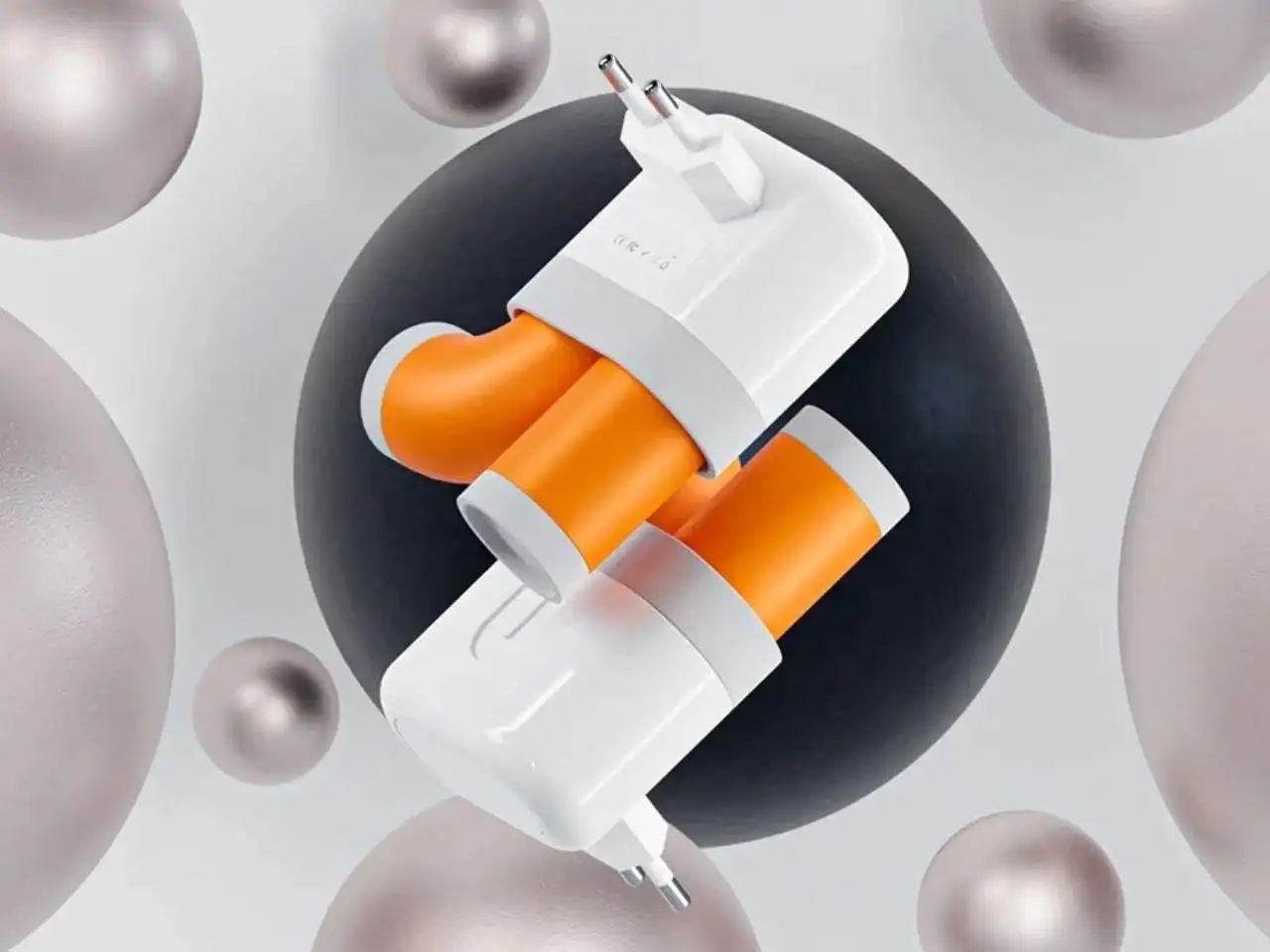

新材料、新工艺的爆发(如 3D 打印表面纹理、环保再生材料、智能变色涂层),让 CMF 的实现难度呈指数级上升:

一款 “渐变色玻璃背板”,需协调染料供应商(色浆稳定性)、玻璃加工厂(镀膜温度对色彩的影响)、组装厂(防刮擦包装工艺),任何环节偏差都会导致 “设计图很美,量产色差大”;

环保材料(如再生 PET)的应用,需平衡 “降解性能” 与 “表面硬度”—— 这需要专人深入供应链,测试不同批次材料的稳定性,甚至参与工艺改良(如调整注塑温度以优化再生料的表面光泽)。

工业设计师的核心能力是 “形态创意”,而 CMF 岗位的核心是 “技术转化”:既要懂设计美学,又要懂材料力学、化工原理、供应链管理,才能避免 “设计空想”,让创意落地为可量产的产品。

品牌调性需要 “系统沉淀”,CMF 是品牌识别的 “隐形锚点”

成熟品牌的调性往往通过 CMF 形成强记忆点:苹果的 “极简白 + 铝合金阳极氧化”、戴森的 “亮紫 + 工程塑料高光”、无印良品的 “米白 + 再生纸浆”…… 这些并非偶然,而是需要专人将品牌价值观(如 “科技感”“环保”)转化为统一的 CMF 标准:

例如,宜家的 “北欧风”,其 CMF 手册会明确 “木色需保留 30% 的自然纹理”“金属件必须用哑光喷砂(避免工业感)”,确保不同品类(沙发、灯具、餐具)的视觉语言一致;

新能源汽车品牌为强化 “未来感”,CMF 岗位会制定 “禁止高饱和色”“优先使用肤感 PU 替代传统皮革” 等规则,让车型从内饰到外观形成统一的品牌认知。

这种系统性的品牌资产沉淀,若由各产品线设计师各自决策,极易导致 “品牌调性碎片化”(如同一品牌的冰箱用金属色、烤箱用彩色,削弱用户认知)。

个性化与小批量定制成趋势,CMF 需快速响应 “柔性生产” 需求

当下用户对 “专属感” 的需求(如汽车的 “定制车漆”、手机的 “联名配色”),倒逼企业从 “大规模量产” 转向 “柔性生产”。而 CMF 是定制化的核心载体:

例如,运动品牌的 “鞋款定制”,用户可选择鞋面材质(网布 / 皮革)、鞋带颜色(10 + 选项)、Logo 烫金 / 烫银 —— 这需要 CMF 岗位提前规划 “可定制的材质库”,并与供应链协商小批量生产的工艺可行性(如数码印花替代传统丝网印,降低小单成本);

智能家居的 “场景化定制”(如卧室款用低蓝光材质、厨房款用防油涂层),需 CMF 岗位根据场景功能快速匹配材料方案,而非等工业设计完成后再 “补位”。

CMF 岗位的独立,是 “设计专业化” 与 “商业价值化” 的必然

当 CMF 从 “让产品好看” 升级为 “传递情感、制造差异、沉淀品牌、控制成本、响应定制” 的综合载体时,其专业性已远超传统工业设计的覆盖范围。独立的 CMF 岗位,本质是企业用 “专人专岗” 的方式,将这一 “感官竞争力” 系统化、可复制化 —— 最终实现 “用户愿意为体验买单,市场愿意为差异溢价” 的商业目标。

@NINEIDEA九号创新 www.nineidea.com

Why do companies establish CMF industrial design positions? From “Design supporting role” to “Competitive Core”

NINEIDEA: The establishment of independent CMF industrial design posts by enterprises is in essence an inevitable choice to cope with consumption upgrading, market competition and industrial complexity improvement. The independence of this position is due to the logical transformation of CMF (color, material, surface treatment) from a “design accessory link” to a “product core competitiveness carrier”.

Consumer demand has shifted from “functional satisfaction” to “experience premium”, and CMF has become the core carrier of emotional connection

The expectation of contemporary users for products has gone beyond “being able to use”, and they are more “feeling” – visual pleasure, tactile comfort, and even cultural symbols of material transmission (such as the micro cement texture of “侘侘侘侘侘侘侘侘侘侘侘侘侘侘侘侘. And CMF is the “first language” that directly touches the user’s senses:

For example, young people’s preference for “healing” household appliances relies on CMF to convey a “gentle feeling” through “milky white+frosted ABS”;

The pursuit of “luxury” by high-end users requires CMF to replace traditional electroplating with “matte metal+nano coating” (which is more environmentally friendly and has a finer texture).

The precise implementation of these experiences requires dedicated personnel to deeply cultivate users’ sensory preferences and cultural trends (such as Pantone’s annual color and popular materials on Xiaohongshu), rather than industrial designers who focus more on form and function, making it difficult to delve into details such as “how white with different color temperatures affects sleep” and “the difference in texture depth of 0.1mm on tactile sensation”.

Market homogenization is severe, and CMF has become a low-cost breakthrough for differentiated competition

In industries where technological iteration is slowing down and product forms are converging (such as 3C, home appliances, and automobiles), CMF is the most likely differentiation path to form memory points. For example:

In the mobile phone industry, when hardware parameter differences are reduced, Huawei Mate series’ “plain leather back cover” (material innovation) and OPPO’s “flow crystal diamond process” (surface treatment) become the core selling points;

In the home appliance industry, Xiaomi’s “white minimalist+anodized aluminum” and Midea’s “Morandi color series+matte enamel” differentiate the different positioning of “young technology” and “home integration” through CMF.

This differentiation requires dedicated personnel to continuously track new materials (such as bio based plastics, graphene coatings), new processes (such as laser micro carving, magnetron sputtering), and transform them into a practical design language – if industrial designers take care of both, it often leads to “following trends and imitating” rather than “innovative breakthroughs” due to scattered energy.

The complexity of supply chain and process has skyrocketed, requiring dedicated personnel to break through the barriers to implementation of “design mass production”

The explosion of new materials and processes (such as 3D printed surface textures, environmentally friendly recycled materials, and intelligent color changing coatings) has exponentially increased the difficulty of implementing CMF

A “gradient color glass back panel” requires coordination with dye suppliers (color paste stability), glass processing plants (impact of coating temperature on color), and assembly plants (scratch resistant packaging process). Any deviation in any link can lead to “beautiful design drawings but large color differences in mass production”;

The application of environmentally friendly materials (such as recycled PET) requires a balance between “degradation performance” and “surface hardness” – this requires dedicated personnel to go deep into the supply chain, test the stability of different batches of materials, and even participate in process improvements (such as adjusting injection molding temperature to optimize the surface gloss of recycled materials).

The core competency of industrial designers is “form creativity”, while the core of CMF positions is “technology transformation”: understanding both design aesthetics, material mechanics, chemical principles, and supply chain management is necessary to avoid “design fantasies” and turn creativity into mass-produced products.

Brand tone requires “systematic sedimentation”, and CMF is the “invisible anchor” of brand recognition

The tone of mature brands often forms strong memory points through CMF: Apple’s “minimalist white+aluminum alloy anodizing”, Dyson’s “bright purple+engineering plastic highlight”, MUJI’s “rice white+recycled pulp”… These are not accidental, but require dedicated personnel to translate brand values (such as “technological sense” and “environmental protection”) into unified CMF standards:

For example, IKEA’s “Nordic style” will clearly state in its CMF manual that “wood color should retain 30% of natural texture” and “metal parts must be sandblasted with matte finish (to avoid industrial feel)” to ensure consistent visual language across different categories (sofas, lighting fixtures, tableware);

In order to enhance the “sense of the future” of new energy vehicle brands, CMF positions will formulate rules such as “prohibiting high saturation colors” and “prioritizing the use of skin feel PU instead of traditional leather”, so as to form a unified brand awareness from interior to exterior of the vehicle models.

This systematic accumulation of brand assets, if decided by designers of each product line, can easily lead to “brand tone fragmentation” (such as using metallic colors for refrigerators and colored colors for ovens of the same brand, weakening user perception).

Personalization and small batch customization have become a trend, and CMF needs to quickly respond to the demand for “flexible production”

The current demand for “exclusivity” among users (such as “customized car paint” for cars and “co branded color matching” for mobile phones) has forced companies to shift from “mass production” to “flexible production”. And CMF is the core carrier of customization:

For example, in the “shoe customization” of sports brands, users can choose shoe upper materials (mesh/leather), shoelace colors (10+options), logo hot stamping/silver stamping – this requires the CMF position to plan a “customizable material library” in advance and negotiate with the supply chain on the feasibility of small-scale production processes (such as digital printing replacing traditional screen printing to reduce small order costs);

The “scenario based customization” of smart homes (such as using low blue light materials for bedroom styles and oil resistant coatings for kitchen styles) requires CMF positions to quickly match material solutions based on scene functions, rather than waiting for industrial design to be completed before “filling in”.

The independence of CMF positions is an inevitable result of “design specialization” and “commercial value”

When CMF is upgraded from “making products look good” to a comprehensive carrier that “conveys emotions, creates differences, precipitates brands, controls costs, and responds to customization”, its professionalism has far exceeded the coverage of traditional industrial design. The independent CMF position is essentially a way for enterprises to systematize and replicate this “sensory competitiveness” through the use of “dedicated personnel” – ultimately achieving the business goal of “users willing to pay for the experience, and the market willing to pay a premium for differentiation”.

@NINEIDEA九号创新 www.nineidea.com