NINEIDEA:在深圳将产品设计从创意到落地,需像齿轮咬合般推进各环节。首先明确 “解决什么痛点”—— 比如发现耳机易脱落或户外电源笨重,通过团队头脑风暴捕捉灵感,如磁吸挂绳耳机、折叠电源等,用草图或短视频记录雏形。

化身 “市场侦探”:

调研淘宝京东竞品价格与差评(如 “重量超标”、“散热差”),访谈目标用户(如年轻人、户外爱好者)确认需求,逛深圳国际工业设计大展等展会捕捉趋势。深圳供应链优势显著,从宝安模具厂到华强北元器件市场,2 小时车程内可完成资源摸底。

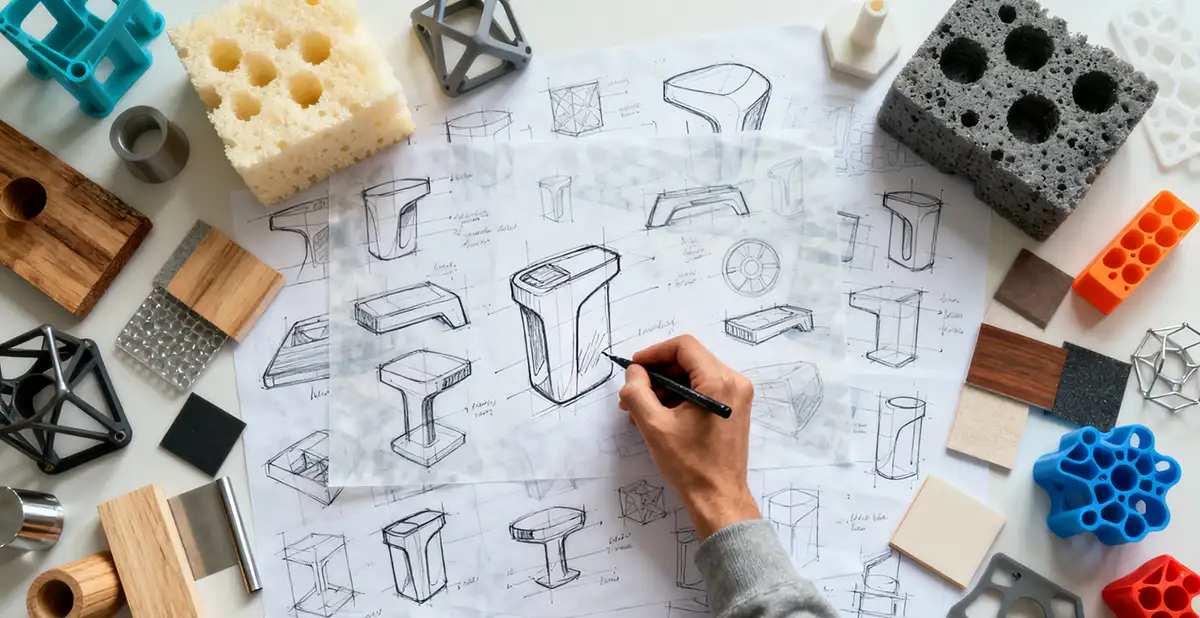

随后进入设计开发阶段:

先手绘勾勒多版草图,再以 Rhino/SolidWorks 构建 3D 模型,通过渲染赋予材质色彩(如哑光黑外壳、金属银按键),深圳设计公司常可在数日内提供高清效果图,直观呈现产品质感。

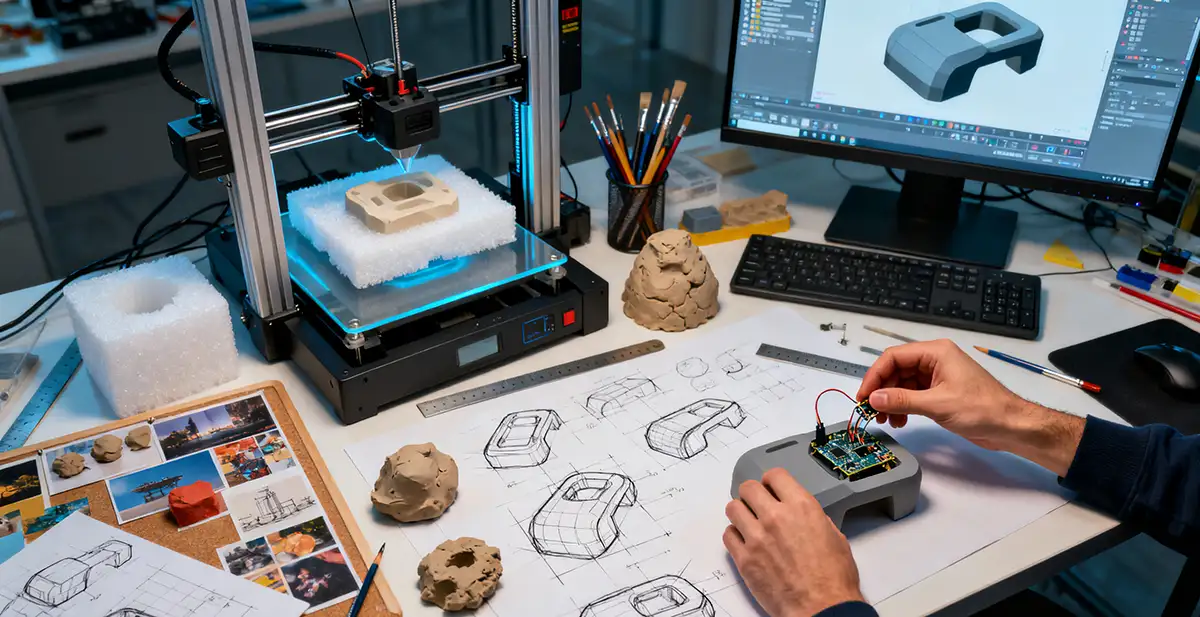

打样环节需制作手板验证设计:

依托深圳密集的手板厂,通过 3D 打印或 CNC 加工快速产出样品,如试戴耳机测试舒适度、插拔电源测试接口手感,即便手板存在缝隙偏差等问题,也能及时暴露设计缺陷(如线材易断裂、指示灯刺眼)。

测试优化阶段需 “内外挑刺”:

内部团队模拟真实场景高频使用(如戴耳机跑步、电源连续充电),外部招募 10-20 名用户免费试用一周,收集 “耳套磨耳”、“散热不足” 等反馈,针对性调整设计直至成熟。

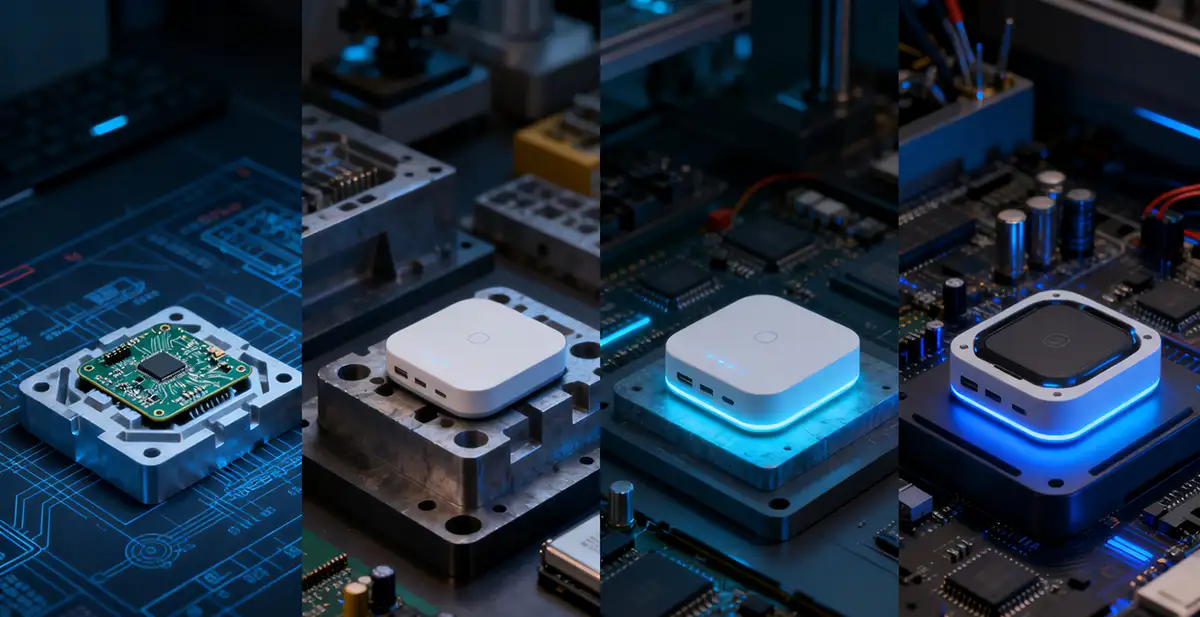

量产环节依托大湾区供应链:

赴东莞 / 惠州工厂洽谈打样,小批量试产(如 100 台)验证工艺稳定性,注塑件需开模(成本数万至数十万),需与工厂反复核对图纸。生产时派驻工程师驻厂把控组装、品检等工序,确保大货与样品一致。

上市前完成 “包装营销组合拳”:

设计环保纸盒或开窗包装凸显卖点(如 “20g 超轻”、“30 分钟快充”),拍摄科技园 / 街头场景短视频投放抖音小红书,参展深圳礼品展对接经销商,同步在电商平台开启预售。线下铺入顺电等数码门店,线上通过物流覆盖全国,同步收集用户反馈为迭代铺路。

深圳模式的核心在于 “快与整合”:

选择鼎典设计等 “设计 + 供应链” 一体化公司可压缩周期,3-6 个月内完成从创意到上市;及时申请外观专利(深圳知识产权局办事便捷)防范抄袭。

从灵感闪现到货架陈列,深圳的产品设计全流程既需打磨用户体验的 “绣花功夫”,也需善用珠三角产业链集群的 “硬核效率”,让创意以最快速度接受市场检验。

Product design, from creativity to implementation, lacks embroidery skills, only hardcore efficiency

NINEIDEA: From creativity to implementation, product design in Shenzhen needs to be pushed forward like gears. Firstly, clarify the “pain points to be solved” – for example, if you find that headphones are prone to falling off or outdoor power sources are bulky, capture inspiration through team brainstorming, such as magnetic drawstring headphones, foldable power sources, etc., and record the prototype with sketches or short videos.

Become a ‘market detective’:

Conduct research on the prices and negative reviews of competitors on Taobao and JD.com (such as “excessive weight” and “poor heat dissipation”), interview target users (such as young people and outdoor enthusiasts) to confirm their needs, and visit exhibitions such as the Shenzhen International Industrial Design Exhibition to capture trends. Shenzhen has significant advantages in the supply chain, with a 2-hour drive from Bao’an Mold Factory to Huaqiang Beiyuan Device Market to complete resource mapping.

Subsequently entering the design and development phase:

First, sketch multiple versions by hand, and then build a 3D model using Rhino/SolidWorks. By rendering and assigning material colors (such as matte black shell, metal silver buttons), Shenzhen design companies can often provide high-definition renderings within a few days, visually presenting the texture of the product.

Prototype verification design is required during the sampling process:

Relying on the dense prototype factories in Shenzhen, samples can be quickly produced through 3D printing or CNC machining, such as testing comfort when trying on headphones, testing the feel of power interfaces when plugging in and out. Even if there are gaps or deviations in the prototype, design defects can be exposed in a timely manner (such as easily broken wires and eye piercing indicator lights).

The testing optimization phase requires “internal and external nitpicking”:

The internal team simulates high-frequency usage in real scenarios (such as running with headphones and continuous power charging), and recruits 10-20 external users for a free one week trial to collect feedback on “ear wear” and “insufficient heat dissipation”, and make targeted adjustments to the design until maturity.

Mass production relies on the Greater Bay Area supply chain:

Go to Dongguan/Huizhou factory to negotiate and make samples, conduct small-scale trial production (such as 100 units) to verify process stability. Injection molded parts need to be molded (costing tens of thousands to hundreds of thousands), and drawings need to be repeatedly checked with the factory. During production, engineers are stationed at the factory to control assembly, quality inspection, and other processes, ensuring that the bulk goods are consistent with the samples.

Complete the ‘Packaging Marketing Combination Fist’ before going public:

Design environmentally friendly cartons or window opening packaging to highlight selling points (such as “20g ultra light”, “30 minute quick charging”), shoot short videos of science park/street scenes to launch Tiktok Little Red Book, participate in Shenzhen Gift Fair to connect dealers, and simultaneously open pre-sales on e-commerce platforms. Offline deployment in digital stores such as Shundian, online coverage across the country through logistics, and synchronized collection of user feedback to pave the way for iteration.

The core of the Shenzhen model lies in “speed and integration”:

Choosing a “design+supply chain” integrated company such as Dingdian Design can compress the cycle and complete the process from creativity to listing within 3-6 months; Timely application for design patents (convenient for Shenzhen Intellectual Property Office) to prevent plagiarism.

From inspiration to shelf display, the entire product design process in Shenzhen requires not only polishing the “embroidery skills” of user experience, but also making good use of the “hardcore efficiency” of the Pearl River Delta industrial chain cluster, allowing creativity to be tested by the market at the fastest speed.