NINEIDEA:ID产品设计师要不要懂结构?学不学结构软件,就像问厨师要不要学配菜:

如果你只想炒出好看的菜(专注外观设计),那知道基本配菜逻辑就行,比如 “这道菜要配土豆丝得切多粗”,但不用自己上手切;

但如果你想当主厨(把控全流程),那必须知道怎么配菜、怎么选食材,不然客人点个 “酸甜排骨”,你光知道摆盘好看,结果糖和醋比例搞错了,端上桌得被骂。

纯外观设计的 “坑”

我刚入行时特抗拒学结构,觉得 “老娘负责貌美如花,你们负责落地打样”。结果有次设计了个带弧度的香薰机,自我感觉巨高级,MD 工程师一看就叹气:“这弧度模具开出来要多花 10 万,而且卡扣根本卡不住。”

老大把我叫去喝茶:“创意很好,但公司不是做艺术品的,你得知道怎么让想法能卖出去。”

从那以后我才明白:不懂结构的设计,就像画画不看纸张大小,画得再美也可能出格。

偷偷卷的人都在学什么?

曾经部门有个大神,每次提案都能秒过,因为他汇报时会甩两张图:

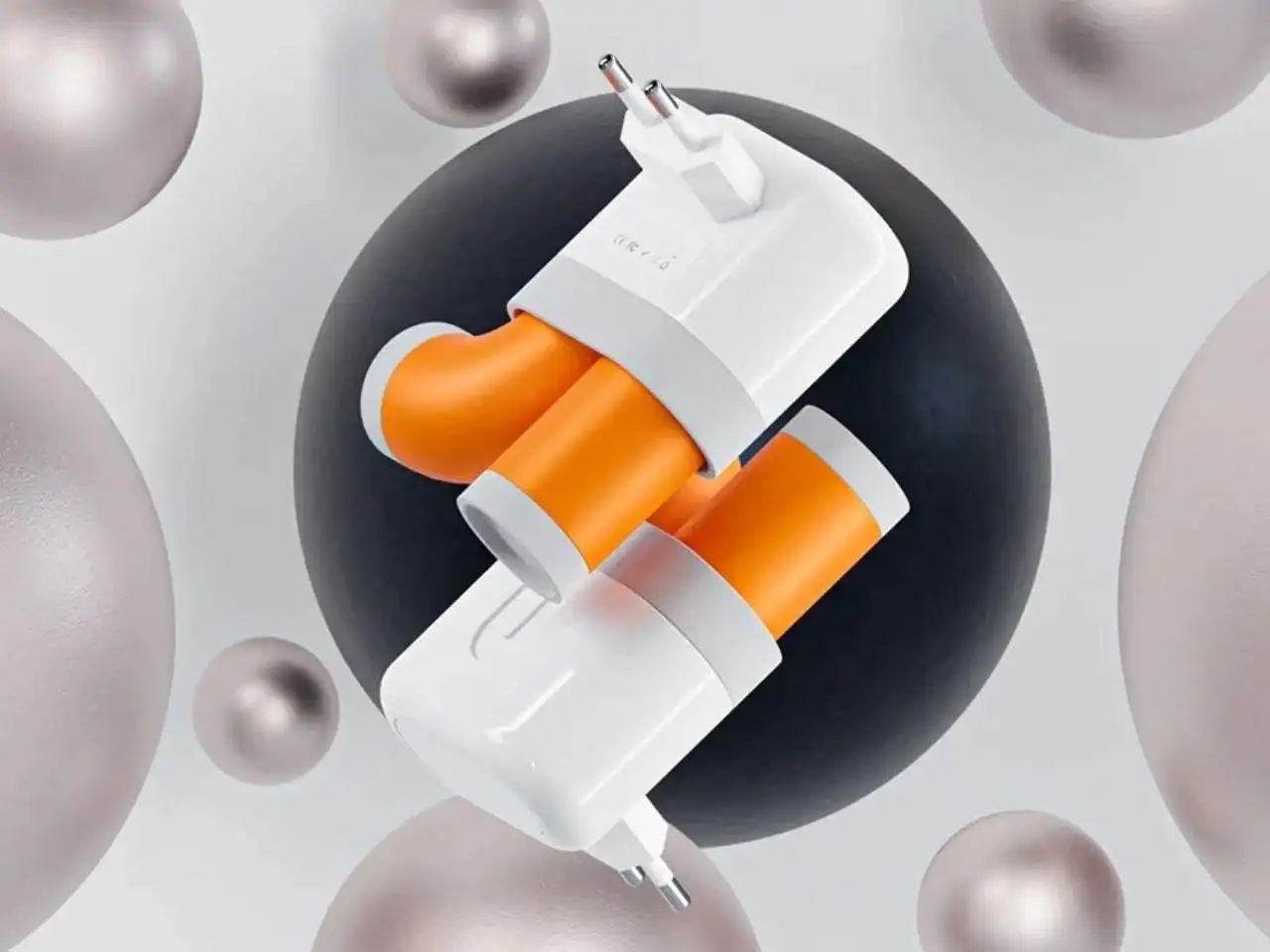

左边是渲染图:“看,鹅卵石手感,哑光材质,用户拿起来不打滑”;

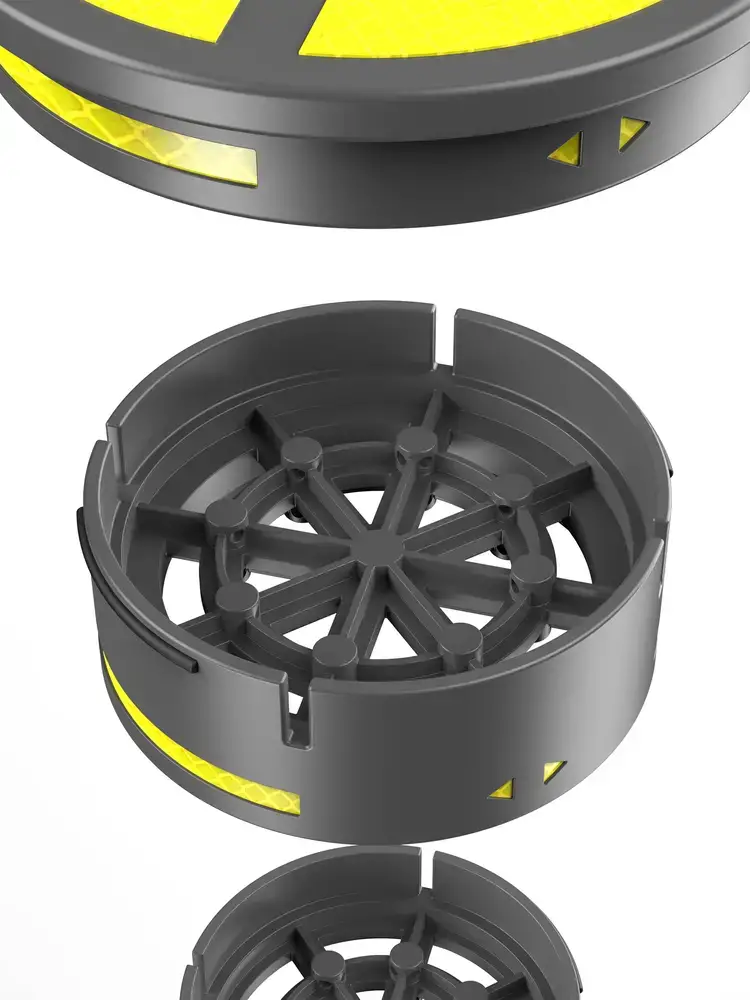

右边是结构爆炸图:“这里做了隐藏式卡扣,拆装方便,模具成本比传统方案低 30%”。

老板当场拍板:“就这个,赶紧推进!”

真相了:懂结构的设计师,一张嘴顶别人十张图。你说 “我这个设计很创新”,不如说 “我用了可拆卸模块化结构后期维修成本降低 50%”,前者是自嗨,后者是直击痛点。

新手别一上来就啃硬骨头!

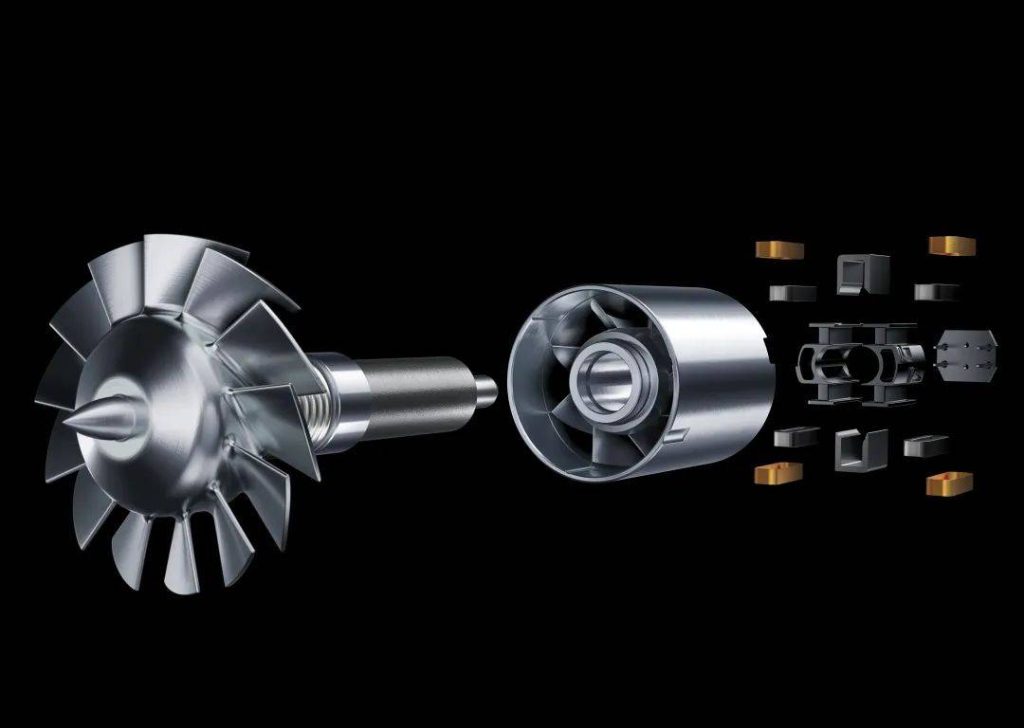

我试过最笨的办法:拿家里的吹风机拆了又装,装了又拆,用手机拍内部结构,然后用 SolidWorks 一点点画。

一开始画个螺丝孔都歪歪扭扭,但拆了 3 个小家电后,突然就懂了:

为什么吹风机出风口要留 2mm 缝隙?因为要给风扇叶片留转动空间;

为什么外壳连接处有斜面?那是拔模斜度,不然模具开不出来。

建议先从 “拆东西” 开始,比看教程有用 100 倍。拆完了试着用简单软件画,比如先学 SketchUp 画个大概结构,再慢慢过渡到专业软件。

市场在筛掉 “纯外观党”

以前我面试时问一个应聘设计师:“你觉得设计和结构怎么配合?” 他说 “我负责设计,结构师负责实现啊”—— 当场就被刷了。

你不懂结构,和工程师沟通时只能说 “能不能改改”,但懂结构的人会说 “这里改成弹簧卡扣,既省空间又增加牢固度”—— 后者才是稀缺人才。

一点小建议

如果你不想长期做设计这一行:不用学精,但至少知道结构师在说什么,别设计出 “反人类” 的东西;

想往上爬:咬咬牙学,把自己变成 “设计 + 结构” 的复合型选手,3 年后你会感谢现在的决定。

设计师的瓶颈从来不是软件,而是能不能让创意落地;

你多懂一点结构,就少求别人一次,多掌握一点主动权。

Do ID product designers need to understand structure?

NINEIDEA: Does the ID product designer understand the structure? Whether to learn structural software or not is like asking a chef if they want to learn side dishes:

If you only want to stir fry dishes that look good (focusing on appearance design), then you just need to know the basic logic of side dishes, such as “how thick to cut this dish with shredded potatoes”, but you don’t have to cut it yourself;

But if you want to be a chef (in charge of the entire process), you must know how to prepare side dishes and choose ingredients. Otherwise, if a customer orders “sweet and sour pork ribs”, you will only know that the dish looks good, but the sugar and vinegar ratio will be wrong, and you will be scolded when it is served on the table.

The “pit” of pure appearance design

When I first started in the industry, I was particularly resistant to learning structure, thinking that ‘Mother is responsible for being beautiful like flowers, and you are responsible for making samples on the ground’. As a result, I once designed an aromatherapy machine with a curved shape, which I felt was extremely high-end. The MD engineer sighed at first glance and said, “This curved mold costs an extra 100000 yuan to make, and the buckle can’t even hold it

The boss called me over for tea and said, “The idea is great, but the company is not in the art industry. You need to know how to sell your ideas

Since then, I have come to understand that not understanding structural design is like drawing without considering the size of the paper. No matter how beautiful the drawing is, it may still go out of line.

What are those who secretly roll up learning?

There used to be a master in the department who could pass every proposal in seconds because he would throw two pictures when reporting:

On the left is the rendering image: “Look, it has a pebble like texture and matte material, making it easy for users to pick up without slipping;

On the right is the exploded view of the structure: “Hidden buckles have been made here, which are easy to disassemble and assemble, and the mold cost is 30% lower than the traditional solution.

The boss made a decision on the spot: ‘That’s it, hurry up and push forward!’

The truth is: A designer who understands structure can open their mouth and show others ten pictures. If you say ‘my design is very innovative’, it’s better to say ‘I used a detachable modular structure, which reduces maintenance costs by 50% in the later stage’ – the former is self interested, and the latter is a direct pain point.

Don’t bite hard bones as soon as you come up!

The dumbest way I’ve ever tried is to take the hair dryer at home and disassemble it again and again, take pictures of the internal structure with my phone, and then draw it bit by bit with SolidWorks.

At first, drawing a screw hole was crooked and twisted, but after dismantling three small appliances, I suddenly understood:

Why does a 2mm gap need to be left at the air outlet of a hair dryer? Because we need to leave room for the fan blades to rotate;

Why is there a sloping surface at the connection of the shell? That’s the draft angle, otherwise the mold won’t come out.

It is recommended to start with “dismantling things”, which is 100 times more useful than watching tutorials. After dismantling, try using simple software to draw, such as learning SketchUp to draw a rough structure first, and then gradually transitioning to professional software.

The market is filtering out the “pure appearance party”

When I interviewed a designer before, I asked him, “How do you think design and structure fit together?” He said, “I am responsible for design, and the structural engineer is responsible for implementation.” – He was rejected on the spot.

You don’t understand the structure, so when communicating with engineers, you can only say ‘can we change it?’ But those who understand the structure will say ‘here we can change it to a spring buckle, which saves space and increases firmness’ – the latter is the scarce talent.

A small suggestion

If you don’t want to work in the field of design for the long term: don’t study hard, but at least know what the structural engineer is saying, don’t design things that are “anti human”;

Want to climb up: grit your teeth and learn, turn yourself into a composite player of “design+structure”, and in 3 years you will be grateful for your current decision.

The bottleneck for designers is never software, but whether they can bring their ideas to fruition;

If you know more about structure, you should ask others less and have more initiative.