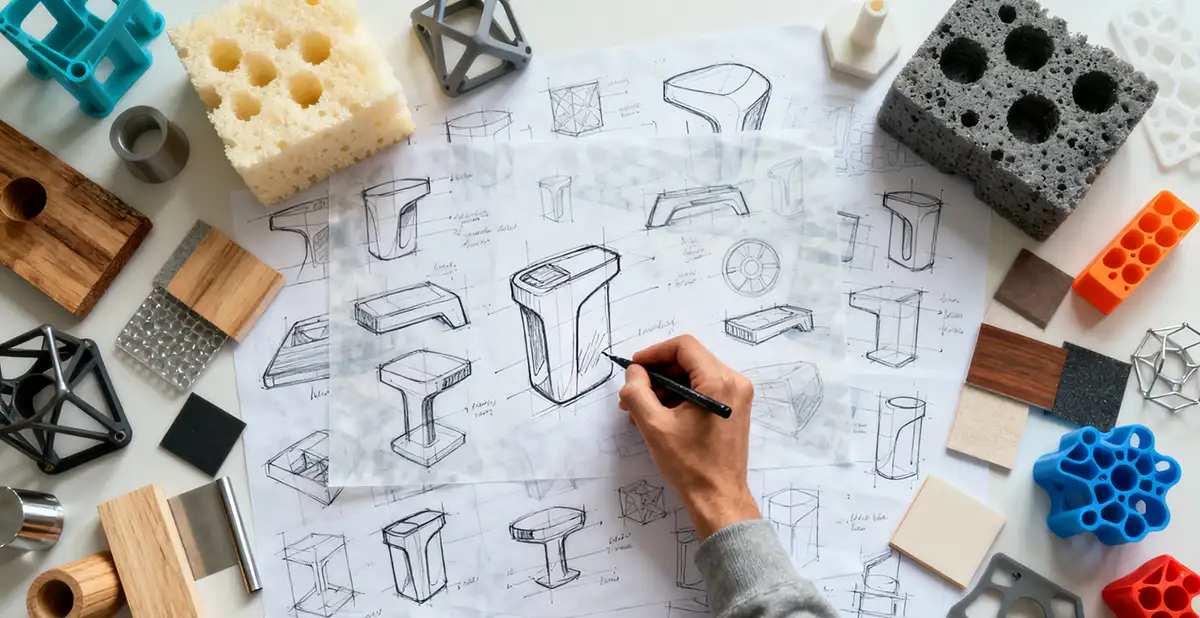

NINEIDEA:CMF设计师的核心价值在于将 “设计创意” 转化为 “可量产的产品体验”,这意味着需要打通从 “源头创新” 到 “终端落地” 的全链条协作,才是CMF设计落地的 “命脉”。具体来说,需重点衔接以下上下游环节:

上游:源头资源链 —— 解决 “用什么做”

材料供应商

基础材料厂商:塑料(如 ABS、PC)、金属(铝、镁合金)、陶瓷、玻璃、纺织品、皮革等原材料供应商,需对接材料性能(强度、耐温、环保性)、成本、配色范围等。

新型材料研发方:生物基材料、再生材料、智能变色材料(如温感 / 光感材料)等创新材料的实验室、企业,获取前沿材料信息,为设计提供差异化选项。

工艺技术方

表面处理厂:电镀、阳极氧化、喷涂(粉末 / 液体)、PVD 真空镀膜、激光雕刻、微纳纹理等工艺供应商,需明确工艺参数(如镀层厚度、喷涂均匀度)、适用材料范围、成本阈值。

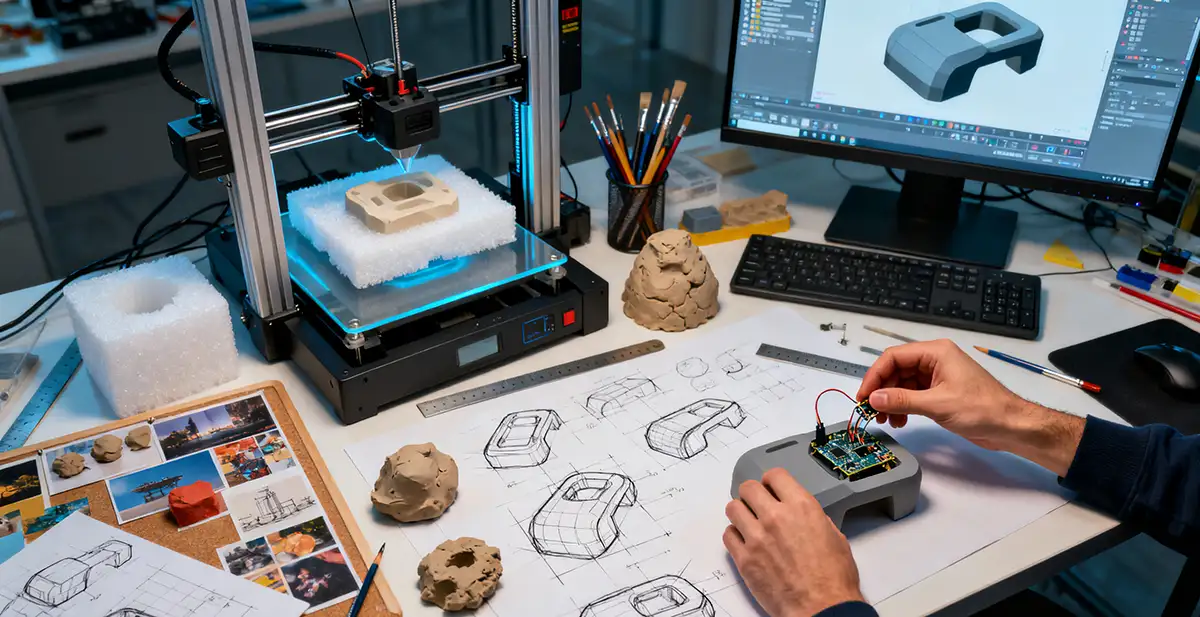

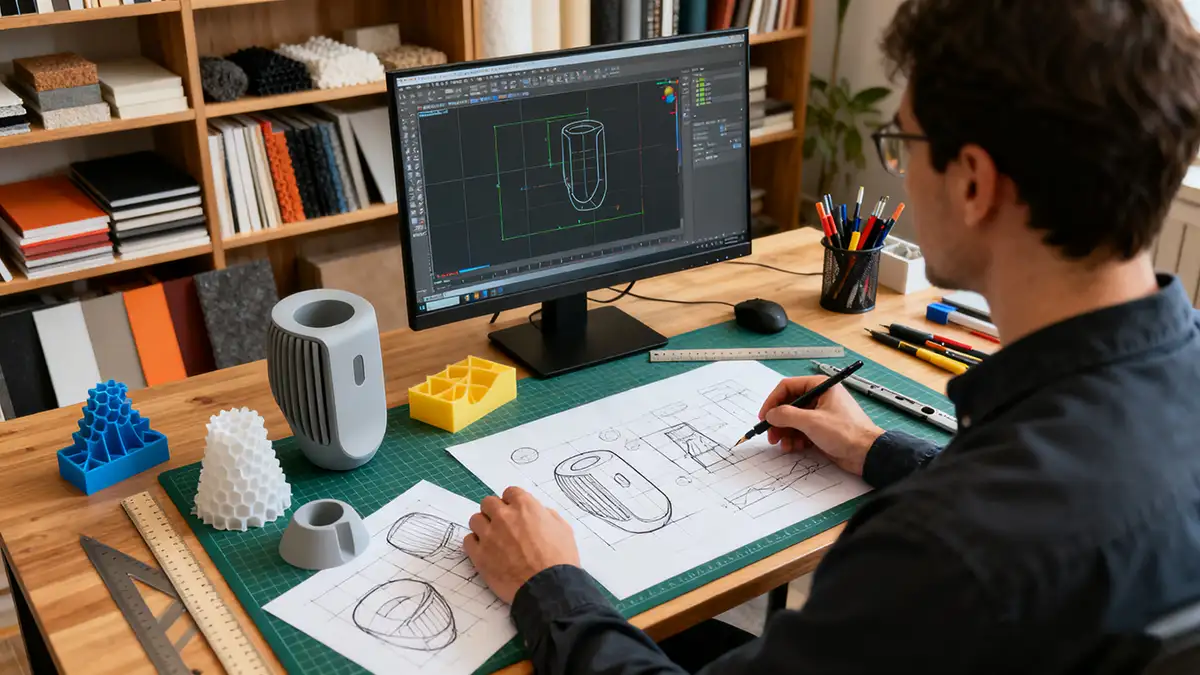

特殊工艺实验室:如 3D 打印表面处理、仿生纹理复制等新兴工艺,对接技术成熟度与量产可行性。

趋势与标准方

色彩趋势机构:如 Pantone、WGSN 等,获取全球色彩流行趋势,确保 CMF 方案符合市场审美周期。

行业标准组织:对接环保标准(如 RoHS、REACH)、安全标准(如儿童产品耐刮擦、食品接触材料认证),确保材料与工艺合规。

中游:设计与协同链 —— 解决 “怎么做”

产品设计团队

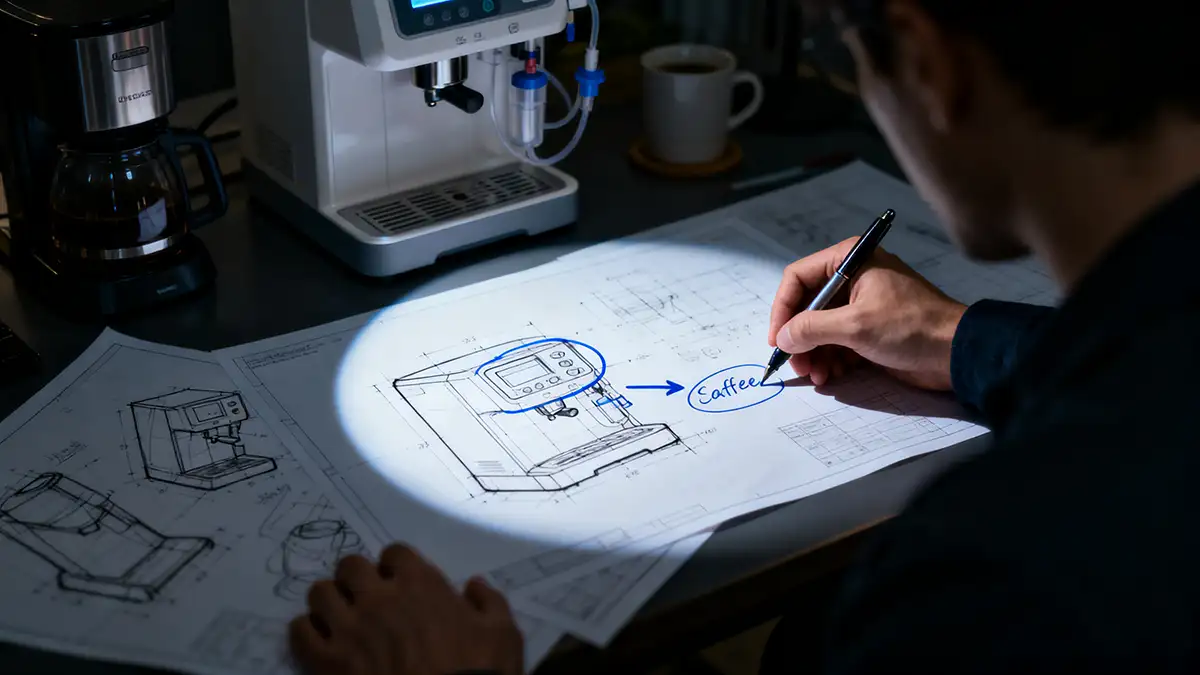

工业设计师:协同产品形态,确保 CMF 方案(如曲面喷涂、异形结构的材质拼接)与造型匹配,避免 “设计好看但做不出来”。

结构工程师:对接材料物理性能(如收缩率、强度)与结构设计(如卡扣强度、装配间隙),例如金属材质可能需要更厚的壁厚,而塑料则需考虑脱模角度对纹理的影响。

供应链与成本团队

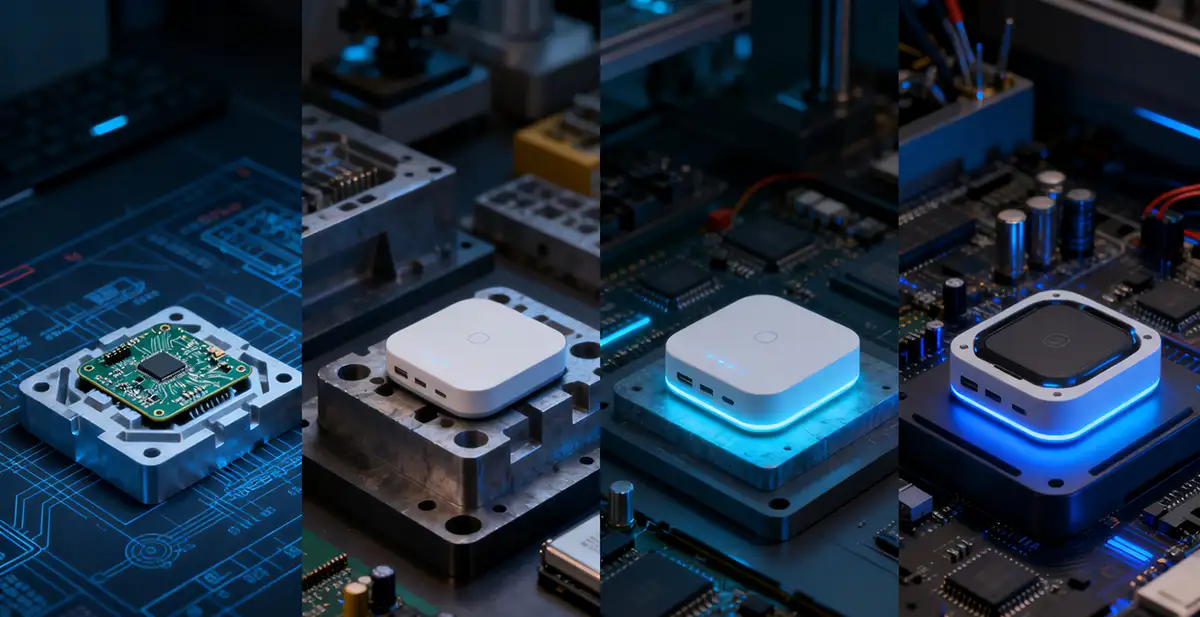

采购部门:同步材料选型与供应商报价,平衡 “设计效果” 与 “成本控制”(如高端 PVD 工艺成本是普通喷涂的 3-5 倍,需评估是否符合产品定价策略)。

生产计划部门:确认工艺量产周期(如阳极氧化需 7-10 天,而普通喷涂 1-2 天),匹配产品上市时间节点。

下游:生产与落地链 —— 解决 “做出什么样”

制造工厂

生产线(注塑、冲压、组装等):对接生产设备参数(如注塑机温度对塑料颜色稳定性的影响)、工人操作规范(如喷涂时的喷枪角度对均匀度的影响),避免批量生产时出现色差、纹理偏差。

品控部门:制定 CMF 验收标准(如色差 ΔE 值≤1.5、耐刮擦等级≥3H),通过打样、试产环节验证标准可行性,确保量产一致性。

终端反馈链

市场与用户:通过用户测试(如握感、视觉偏好)、售后反馈(如材料耐老化性、工艺 durability)优化 CMF 方案,例如某手机机型因后盖喷涂易磨损,后续迭代改用陶瓷材质。

品牌方:对齐品牌调性(如科技品牌常用金属 + 冷色调,轻奢品牌常用皮革 + 暖色调),确保 CMF 方案成为品牌识别的一部分(如苹果的 “深空灰”、戴森的 “蓝紫渐变”)。

CMF 设计师的 “链条核心作用”

本质是 “翻译者” 与 “协调者”—— 将上游的材料 / 工艺可能性、中游的设计与成本约束、下游的生产与用户需求 “翻译” 为统一的 CMF 方案,同时协调各环节的矛盾(如 “想要金属质感但成本太高”“想要特殊纹理但量产不稳定”),最终实现 “设计有创新、生产能落地、用户愿买单” 的闭环。

@NINEIDEA九号创新 www.nineidea.com

Connecting upstream and downstream is the “lifeline” of CMF design implementation

NINEIDEA: The core value of CMF designers is to transform “design creativity” into “mass production product experience”, which means that the whole chain cooperation from “source innovation” to “terminal implementation” is the “lifeblood” of CMF design implementation. Specifically, it is necessary to focus on connecting the following upstream and downstream links:

Upstream: Source Resource Chain – Solving the Problem of ‘What to Do’

Supplier

Basic material suppliers: plastic (such as ABS, PC), metal (aluminum, magnesium alloy), ceramics, glass, textiles, leather and other raw material suppliers, need to coordinate material performance (strength, temperature resistance, environmental protection), cost, color matching range, etc.

New material R&D team: laboratories and enterprises that develop innovative materials such as biobased materials, recycled materials, and intelligent color changing materials (such as temperature sensitive/light-sensitive materials), to obtain cutting-edge material information and provide differentiated options for design.

Process technology provider

Surface treatment plants: suppliers of electroplating, anodizing, spraying (powder/liquid), PVD vacuum coating, laser engraving, micro/nano texture and other processes, need to clarify process parameters (such as coating thickness, spraying uniformity), applicable material range, and cost threshold.

Special process laboratory: for emerging processes such as 3D printing surface treatment, biomimetic texture replication, etc., to connect technology maturity and mass production feasibility.

Trends and Standards

Color trend agencies such as Pantone and WGSN obtain global color trends to ensure that CMF solutions conform to market aesthetic cycles.

Industry standard organizations: Coordinate environmental standards (such as RoHS, REACH) and safety standards (such as children’s product scratch resistance and food contact material certification) to ensure material and process compliance.

Midstream: Design and Collaborative Chain – Solving the “How to Do” Problem

Product Design Team

Industrial designer: Collaborate on product form to ensure that CMF solutions (such as surface spraying and material splicing of irregular structures) match the shape, avoiding the problem of “design looks good but cannot be made”.

Structural engineer: Coordinate the physical properties of materials (such as shrinkage rate and strength) with structural design (such as buckle strength and assembly clearance). For example, metal materials may require thicker wall thickness, while plastic materials need to consider the effect of demolding angle on texture.

Supply Chain and Cost Team

Purchasing department: Synchronize material selection and supplier quotations, balance “design effect” and “cost control” (such as high-end PVD process costs 3-5 times higher than ordinary spraying, need to evaluate whether it conforms to product pricing strategy).

Production Planning Department: Confirm the production cycle of the process (such as 7-10 days for anodizing and 1-2 days for ordinary spraying), and match the product launch time node.

Downstream: Production and landing chain – solving the problem of ‘what to do’

Manufacturing plant

Production line (injection molding, stamping, assembly, etc.): Coordinate production equipment parameters (such as the influence of injection molding machine temperature on plastic color stability), worker operating standards (such as the influence of spray gun angle on uniformity during spraying), to avoid color difference and texture deviation during mass production.

Quality Control Department: Develop CMF acceptance standards (such as color difference Δ E value ≤ 1.5, scratch resistance level ≥ 3H), verify the feasibility of the standards through sampling and trial production processes, and ensure consistency in mass production.

Terminal feedback chain

Market and Users: Optimize CMF solutions through user testing (such as grip and visual preferences) and after-sales feedback (such as material aging resistance and process durability). For example, a certain mobile phone model may use ceramic materials in subsequent iterations due to wear and tear caused by spray coating on the back cover.

Brand side: Align brand tone (such as commonly used metal+cool tones for technology brands, commonly used leather+warm tones for light luxury brands), ensuring that CMF solutions become part of brand identity (such as Apple’s “Deep Space Gray” and Dyson’s “Blue Purple Gradient”).

The ‘Chain Core Role’ of CMF Designers

The essence is the “translator” and “coordinator” – translating upstream material/process possibilities, midstream design and cost constraints, downstream production and user needs into a unified CMF solution, while coordinating conflicts in each link (such as “wanting metallic texture but high cost” and “wanting special texture but unstable mass production”), ultimately achieving a closed loop of “design innovation, production implementation, and user willingness to pay”.

@NINEIDEA九号创新 www.nineidea.com